ABRX High-Performance Rotary Air-Bearing Stages

The ABRX family of high-performance, direct-drive, rotary air-bearing stages delivers the most precise rotational motion available. In addition to bringing you market-leading axial-, radial- and tilt-error motion performance, ABRX stages offer superb rotational accuracy and repeatability, plus impressive load-carrying capabilities – all in a favorable form factor that easily integrates into your multi-axis motion systems and machines.

Description

Specifications

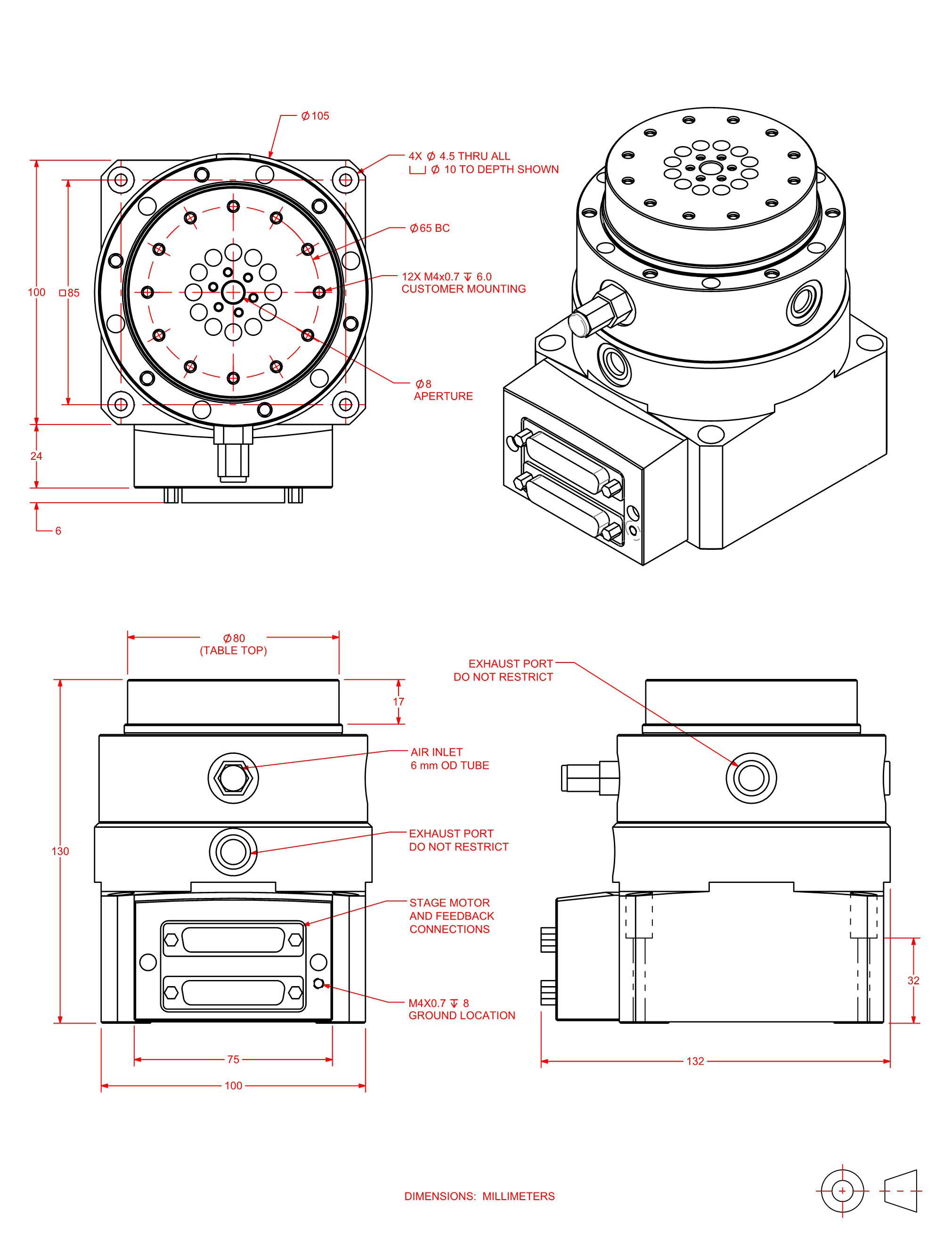

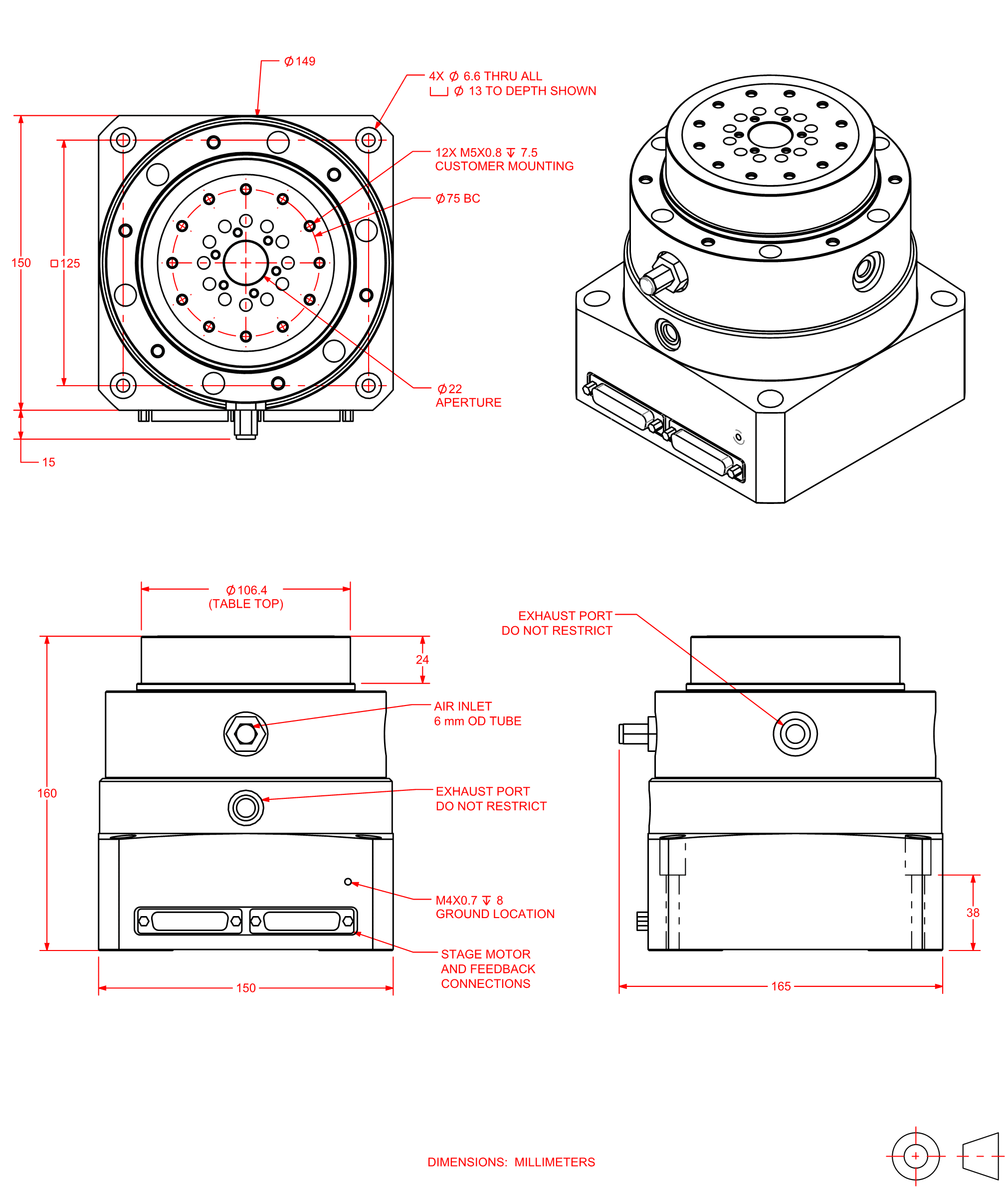

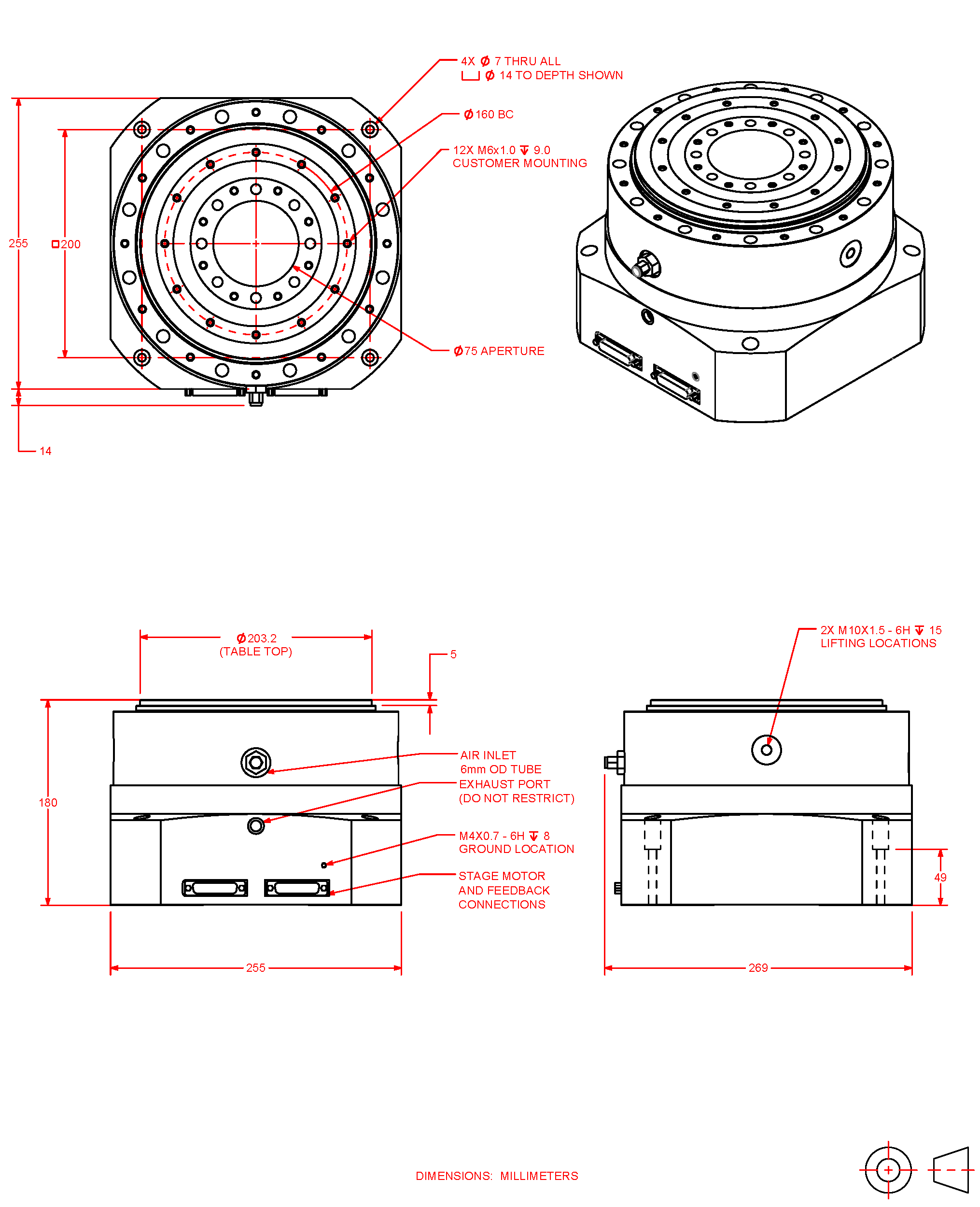

Dimensions

Ordering Info

Downloads

Description

Description

Specifications

Dimensions

Ordering Info

Downloads

Description

Design Features

- Delivers best-in-class rotational motion, helping you to optimize your high-precision process

- Minimizes axial-, radial-, and tilt-error motions, reducing the need for extensive post-processing of parts and measurement data

- Offers excellent positioning performance and velocity stability with high-resolution feedback

- Features a novel, non-influencing motor design that contributes to ultra-precise motion performance

- Provides generous load-carrying capacity without compromising on motion quality

- Integrates easily into precision systems and machines due to compact, lightweight form factor, as well as horizontal and vertical mounting and load-carrying capabilities

Key Applications

ABRX stages are ideal for high-precision applications, including:

- Surface metrology, including the measurement of roundness, flatness, and form error

- Micro- and nanotomography

- Beamline and synchrotron research

- Precision manufacturing, including diamond turning, grinding and other high-performance machine tool applications

- Optical alignment, inspection and calibration systems

Engineered for Precision

The ABRX series is meticulously engineered to consistently satisfy even the most stringent performance requirements. At its core is an industry-leading, air-bearing technology that delivers nanometer-level error motion performance with high stiffness and load-carrying capabilities. The non-influencing, direct-drive, ironless motor was specifically engineered to have virtually zero contribution to axial-, radial- or tilt-error motions, without compromising torque or speed. Coupled with a selection of analog and digital position feedback configurations, including an ultra-fine resolution one volt peak-to-peak (1 Vpp) option capable of achieving sub-microradian minimum incremental motion, ABRX is the ideal rotary stage for applications in which precision is non-negotiable. To this end, all ABRX stages ship with certified plots of calibrated accuracy, repeatability and error motion performance.

Simple, Straightforward Integration

ABRX features an advanced bearing design that provides excellent stiffness and high load capacity, while maintaining compact overall dimensions and reasonably low overall mass. This makes ABRX ideal to use as a component stage in multi-axis motion systems and precision turnkey machines. ABRX stages can be mounted with the axis of rotation oriented either vertically or horizontally. For interfacing with your payloads, the ABRX tabletop is ground flat to minimize distortion and features 12 steel-threaded holes for convenient load placement and orientation. Additionally, a clear aperture through the center of the stage can be used for cable and hose routing or for aiding system-level alignments.

Maintenance-Free Operation

The ABRX’s completely contactless air-bearing and non-influencing motor design ensures years of maintenance-free operation. Zero contact between moving elements means there is no wear or reduction in performance over time, enabling consistent, high-precision motion over a virtually unlimited service life.

Take Your Process to the Next Level

ABRX can achieve the extreme levels of motion and positioning performance required by even the most demanding processes, enabling you to achieve and maintain a competitive advantage while also minimizing risk. Its pristine motion quality minimizes parasitic errors, which allows you to achieve the highest possible processing quality and yield, while minimizing or eliminating the need to perform extensive post-processing operations.

Ordering Information

ABRX High-Performance Rotary Air-Bearing Stage

| Option | Description |

| ABRX100 | ABRX100 high-performance rotary air-bearing stage |

| ABRX150 | ABRX150 high-performance rotary air-bearing stage |

| ABRX250 | ABRX250 high-performance rotary air-bearing stage |

Feedback (Required)

| Option | Description |

| -E1 | Incremental encoder, 1 Vpp |

| -E2 | Incremental encoder, 1 Vpp, high performance |

| -E3 | Incremental encoder, Digital RS422, electrical resolution 0.130 arc sec (ABRX100, ABRX150) or 0.116 arc sec (ABRX250) |

- Maximum speed with -E3 option is limited to 170 rpm for ABRX100 and ABRX150, and 155 rpm for ABRX250.

Integration (Required)

| Option | Description |

| -TAS | Integration - Test as system Testing, integration, and documentation of a group of components as a complete system that will be used together (ex: drive, controller, and stage). This includes parameter file generation, system tuning, and documentation of the system configuration. |

| -TAC | Integration - Test as components Testing and integration of individual items as discrete components that ship together. This is typically used for spare parts, replacement parts, or items that will not be used together. These components may or may not be part of a larger system. |

- Aerotech offers both standard and custom integration services to help you get your system fully operational as quickly as possible. The following standard integration options are available for this system. Please consult Aerotech if you are unsure what level of integration is required, or if you desire custom integration support with your system.