ABRT Air-Bearing Direct-Drive Rotary Stage

Our ABRT series rotary air-bearing stages provide superior angular positioning, velocity stability and error motion performance along with impressive payload capacity and outstanding radial and axial stiffness. The ABRT is designed to meet the exacting requirements of wafer inspection, high precision metrology applications, X-ray diffraction systems, optical inspection and fabrication and MEMS/nanotechnology device fabrication.

Description

Specifications

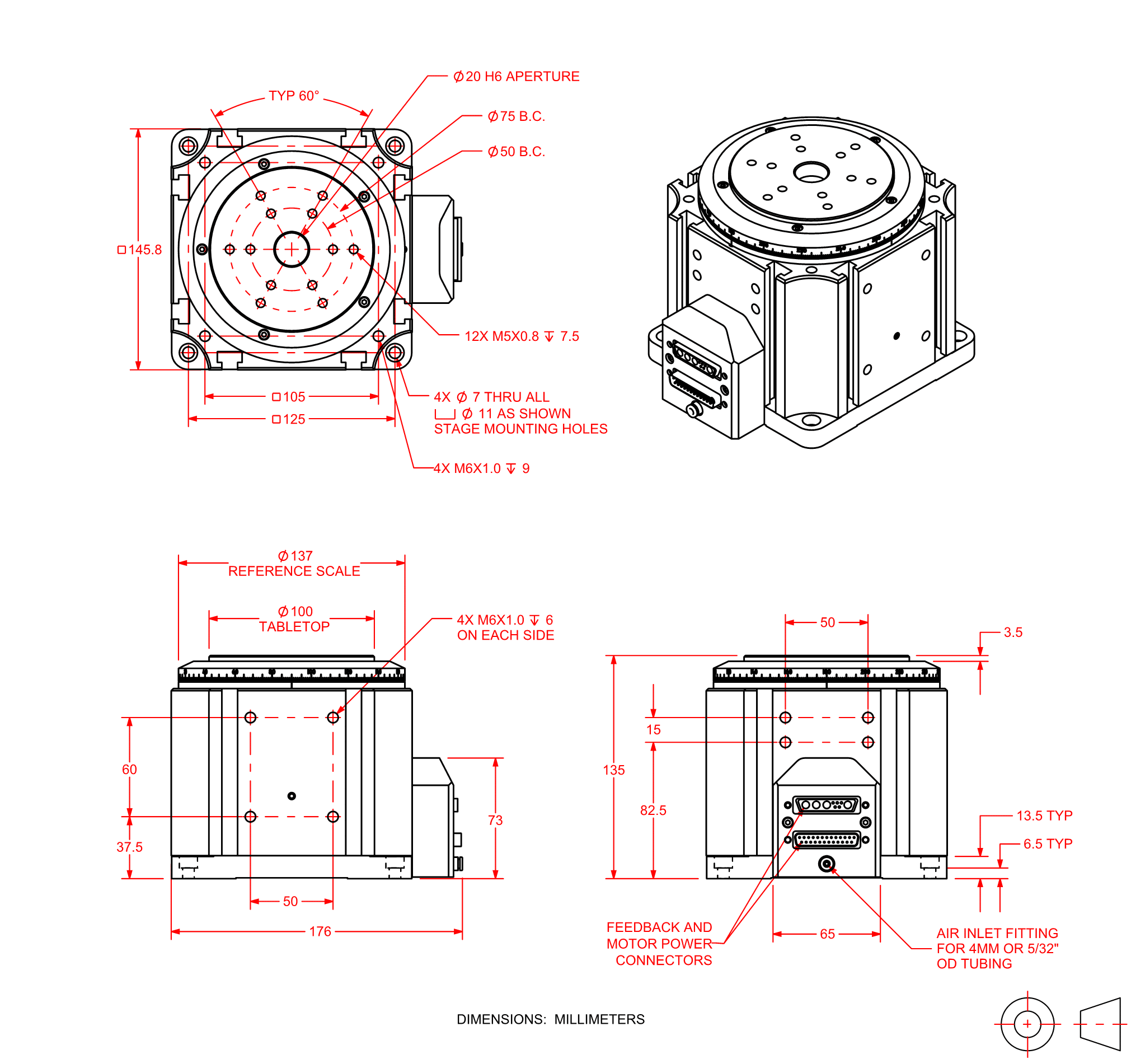

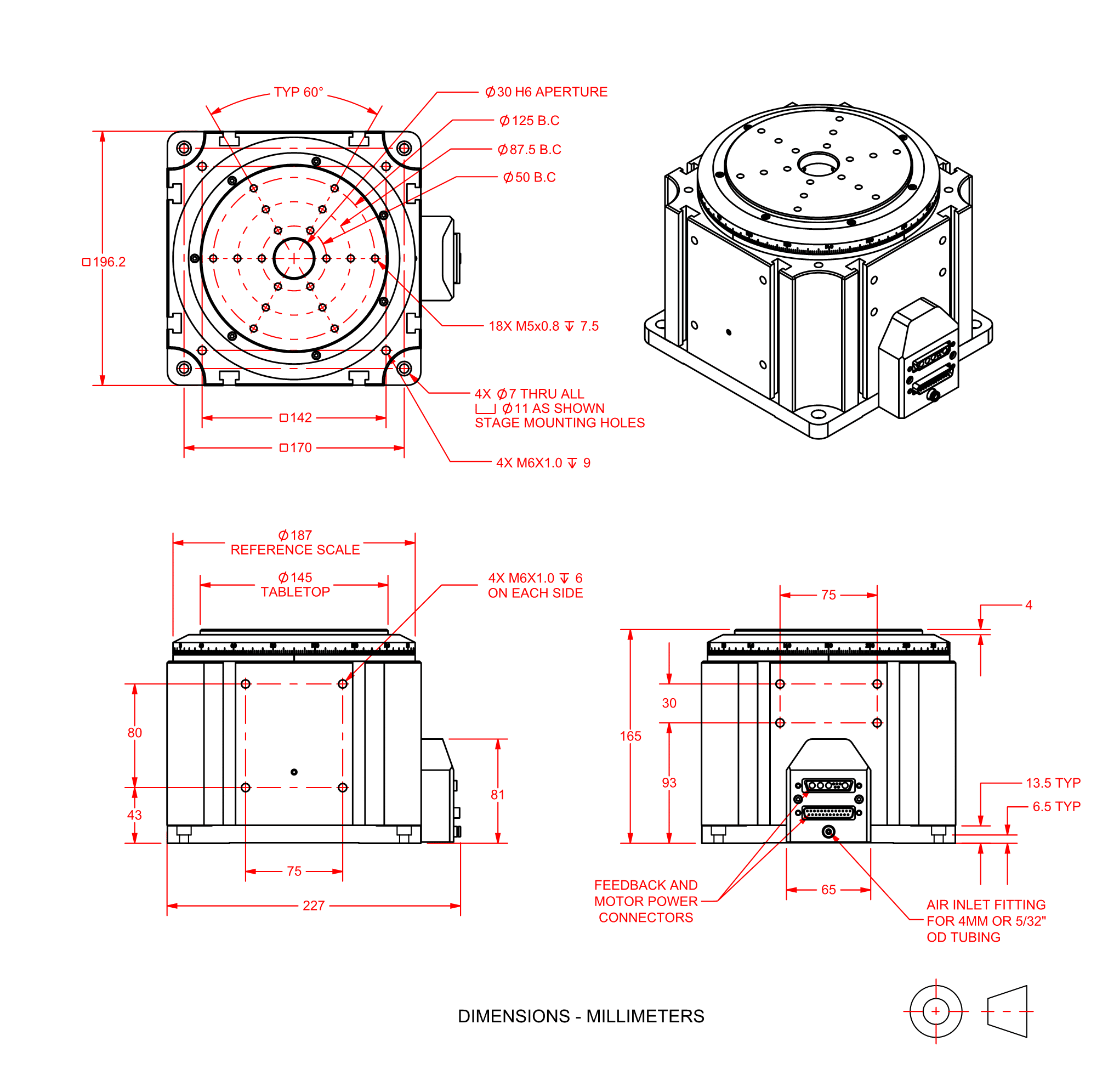

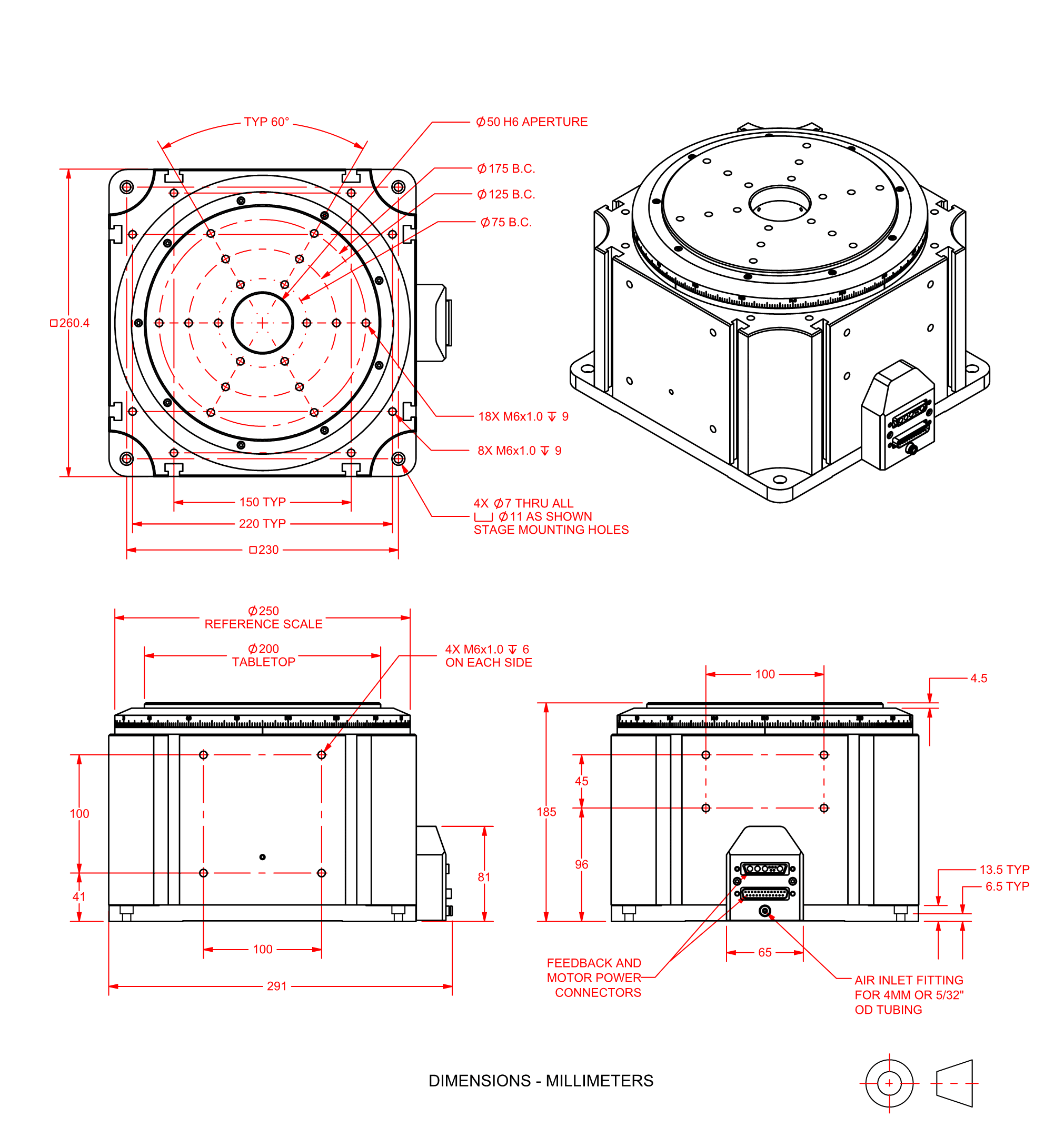

Dimensions

Ordering Info

Downloads

Description

Description

Specifications

Dimensions

Ordering Info

Downloads

Description

Design Features

- High torque output, direct-drive, slotless, brushless servomotor

- Zero-cogging motor for outstanding velocity stability

- Outstanding error motion and wobble performance

- Direct coupled, high-accuracy rotary encoder

- Large diameter clear aperture

- No mechanical contact

Superior Mechanical Design

The ABRT design features large air-bearing surfaces and innovative preloading for high stiffness and load capacity, producing not only excellent axial and radial error motions, but outstanding tilt error motion, as well. The resultant performance is significantly better than other rotary air-bearing tables and spindles, greatly benefiting applications requiring exceptional planar performance. Furthermore, this stage family provides a clear aperture that can be used for product feed-through, laser beam delivery, cable clearance or application-specific requirements.

Brushless Direct-Drive

To maximize positioning performance, the ABRT series utilizes optimized versions of Aerotech's S-series slotless, brushless motor. The motor uses an advanced magnetic circuit design to produce high torque output with minimal heat generation. The slotless design is inherently zero-cogging and torque-ripple-free. This makes ABRT stages ideal for applications requiring smooth scan velocities at low or high speeds.

Accurate Positioning

An optical encoder is standard with the ABRT. When coupled with Aerotech's feedback multipliers and controls, resolutions of <0.03 arc second are achievable.

Custom Designs

Custom versions of the ABRT are available to satisfy rate table and high precision inertial guidance test-stand applications. Other features, such as slip rings and rotary unions, are available.

Flexible Configurations

Aerotech manufactures a wide range of servo amplifiers and advanced controllers to provide a complete, integrated package.

Ordering Information

ABRT Air-Bearing Direct-Drive Rotary Stage

| Option | Description |

| ABRT150 | 150 mm wide air-bearing direct-drive rotary stage |

| ABRT200 | 200 mm wide air-bearing direct-drive rotary stage |

| ABRT260 | 260 mm wide air-bearing direct-drive rotary stage |

Feedback (Required)

| Option | Description |

| -E1 | Incremental encoder, 1 Vpp |

| -E2 | Incremental encoder, TTL, x50 interpolation |

Integration (Required)

Aerotech offers both standard and custom integration services to help you get your system fully operational as quickly as possible. The following standard integration options are available for this system. Please consult Aerotech if you are unsure what level of integration is required, or if you desire custom integration support with your system.

| Option | Description |

| -TAS | Integration - Test as system

Testing, integration, and documentation of a group of components as a complete system that will be used together (ex: drive, controller, and stage). This includes parameter file generation, system tuning, and documentation of the system configuration. |

| -TAC | Integration - Test as components

Testing and integration of individual items as discrete components that ship together. This is typically used for spare parts, replacement parts, or items that will not be used together. These components may or may not be part of a larger system. |

Accessories (To Be Ordered As Separate Line Item)

| Option | Description |

| -ABF | Air-bearing filtration kit |