MPS75SL and SLE Miniature Mechanical-Bearing Screw-Driven Linear Stage

The MPS75SL and MPS75SLE are compact, high-performance linear positioning stages that are perfect for the confines of the laboratory while providing the high reliability required in a production environment. MPS75SLE is equipped with a direct linear encoder for enhanced precision. It is the ideal choice for measurement, testing, accurate alignment and component assembly.

Interested in buying online? Learn more here.

Description

Specifications

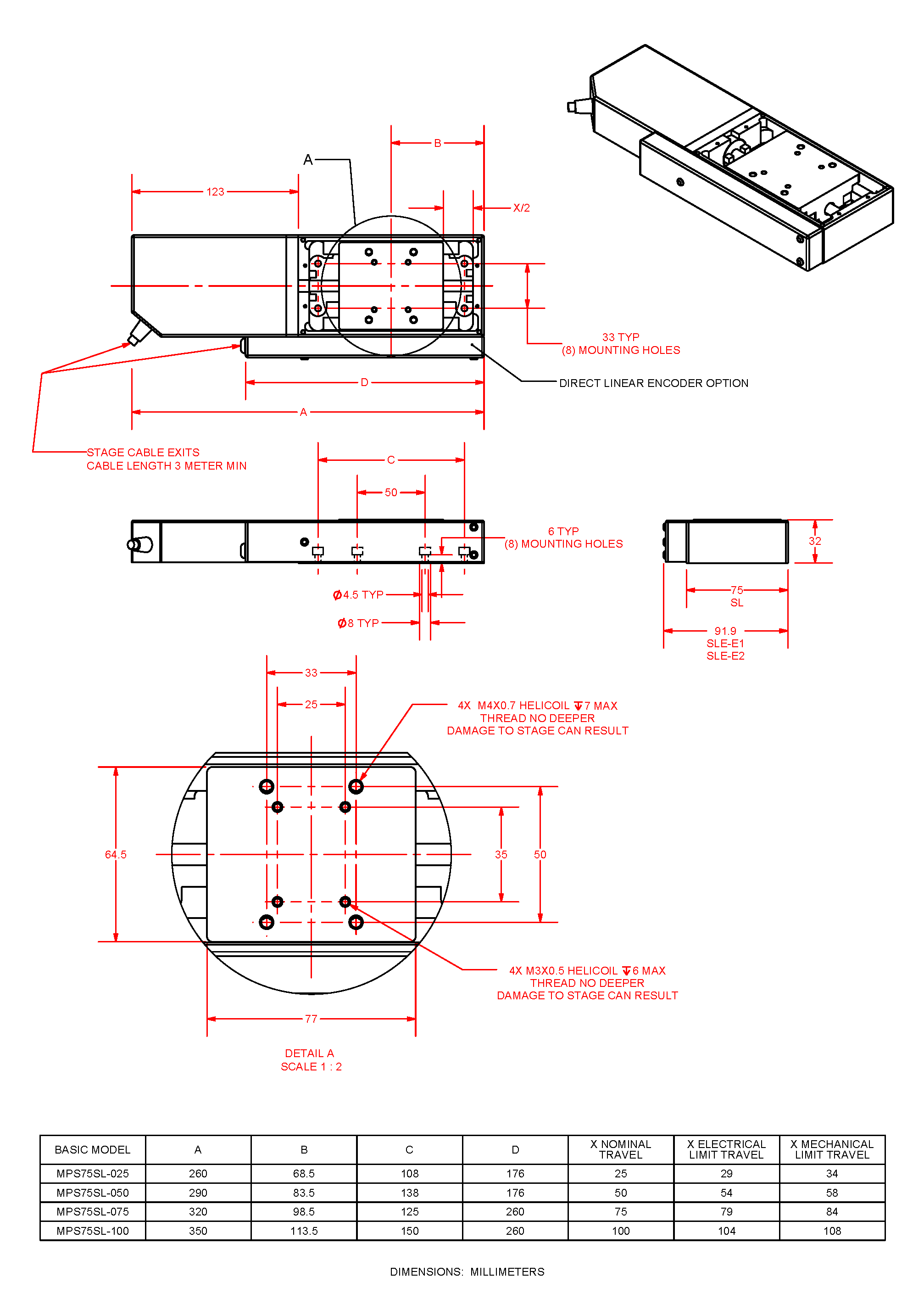

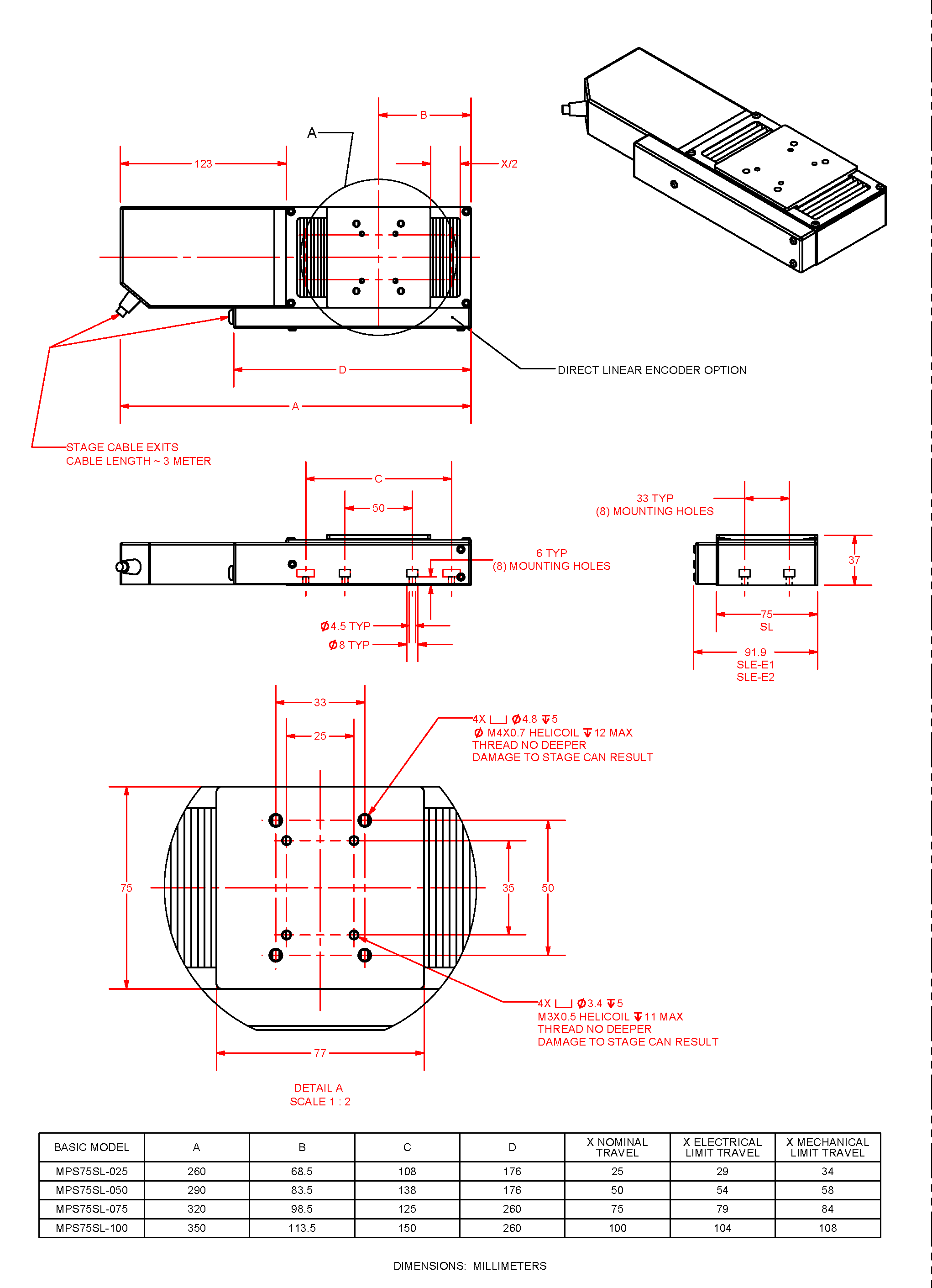

Dimensions

Ordering Info

Downloads

Description

Description

Specifications

Dimensions

Ordering Info

Downloads

Description

Design Features

- Compact 75 mm width with travel to 100 mm

- Precision ground ball-screw drive

- DC servo or stepper motor

- Anti-creep crossed-roller bearings

- High resolution (0.1 µm), repeatability (±0.75 µm) and accuracy (±1.0 µm)

- High-vacuum compatible

- Optional bellows waycovers

- Compact multi-axis configurations

High Accuracy

The precision ground ball-screw provides exceptional accuracy, repeatability and ultra-fine positioning resolution capability to 0.1 micron. The DC servomotor is equipped with a rotary encoder. The anti-creep crossed-roller linear bearings provide smooth travel and excellent payload characteristics.

Optional Vacuum Preparation

The MPS75SL is available with optional vacuum preparation to 10-6 Torr. It is the perfect compact stage choice for today's demanding vacuum applications in markets such as semiconductor manufacturing and inspection, optics fabrication and military/aerospace.

Highly Configurable

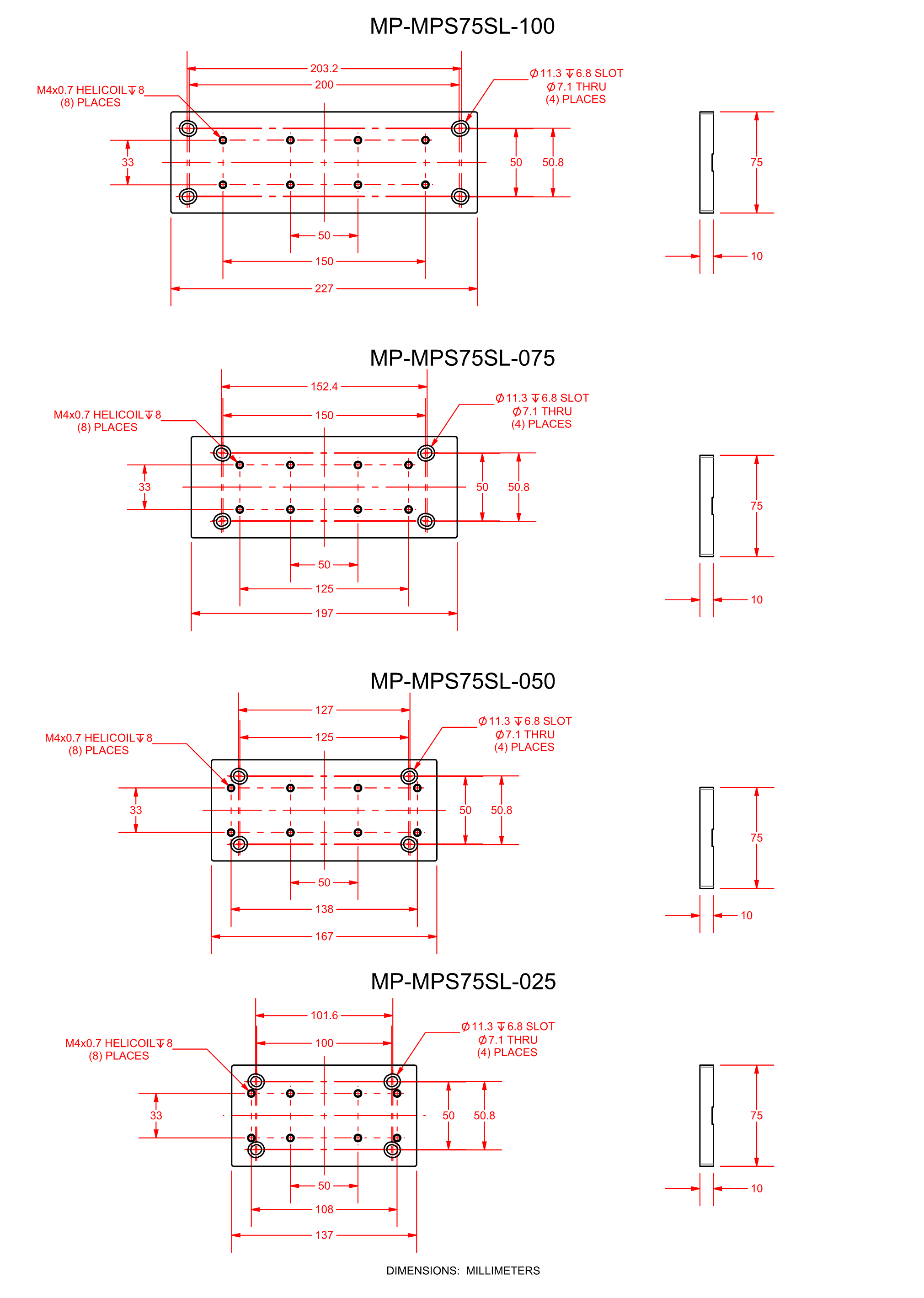

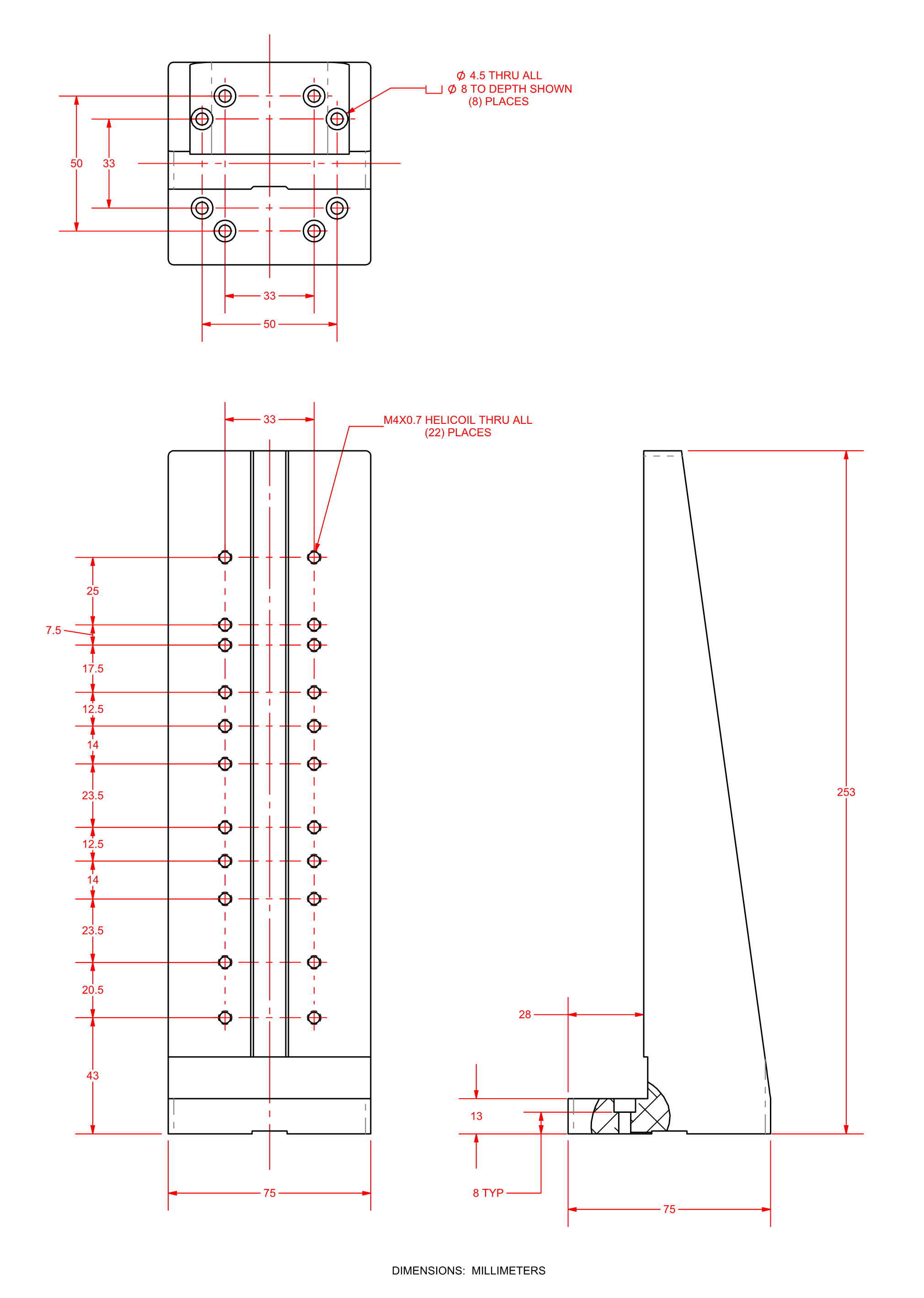

An optional breadboard mounting plate provides direct mounting to both English and metric breadboards. Bellows waycovers are available for use in dusty environments. Any of the models can be mounted in an XY configuration and, with the right-angle L-bracket, in XYZ configurations. It can also be mounted with the smaller MPS50SL stage.

The MPS75SL is a member of the MPS (Miniature Positioning Stage) family of linear, rotary and vertical lift and Z stages. Two or more stages can easily be mounted together in numerous combinations using standardized mounting patterns and adapter plates.

Ordering Information

MPS75SL and SLE Miniature Mechanical-Bearing Screw-Driven Linear Stage

Direct Linear Feedback (MPS75SLE Only)

| Option | Description |

| -E1 | Incremental linear encoder; 1 Vpp |

| -E2 | Incremental linear encoder; 0.05 µm digital TTL output |

Travel (Optional)

| Option | Description |

| -025 | 25 mm travel stage |

| -050 | 50 mm travel stage |

| -075 | 75 mm travel stage |

| -100 | 100 mm travel stage |

Vacuum Preparation (Optional)

| Option | Description |

| -HV | High vacuum preparation to 10-6 Torr |

- Vacuum preparation is not a standard ordering option for -SLE models with direct linear feedback. Contact Aerotech for more information.

Motor (Required)

| Option | Description |

| -M1 | DC servomotor |

| -M2 | Stepper Motor |

Bellows (Optional)

| Option | Description |

| -BL | Bellows waycover |

- Bellows waycover not available with -HV vacuum preparation.

Mounting Plate (Optional)

| Option | Description |

| -MP | Optical table mounting plate |

Metrology (Required)

| Option | Description |

| -PL0 | No metrology performance plots |

| -PL1 | Metrology, uncalibrated with performance plots |

| -PL2 | Metrology, calibrated (HALAR) with performance plots |

Integration (Required)

Aerotech offers both standard and custom integration services to help you get your system fully operational as quickly as possible. The following standard integration options are available for this system. Please consult Aerotech if you are unsure what level of integration is required, or if you desire custom integration support with your system.

| Option | Description |

| -TAS | Integration - Test as system Testing, integration, and documentation of a group of components as a complete system that will be used together (ex: drive, controller, and stage). This includes parameter file generation, system tuning, and documentation of the system configuration. |

| -TAC | Integration - Test as components Testing and integration of individual items as discrete components that ship together. This is typically used for spare parts, replacement parts, or items that will not be used together. These components may or may not be part of a larger system. |

Accessories (to be ordered as separate line item)

| Option | Description |

| HDZ-MPS75SL | Right angle bracket, MPS75SL |

| HDZ-MPS75SL-HV | Right angle bracket, MPS75SL, high vacuum preparation to 10-6 Torr |