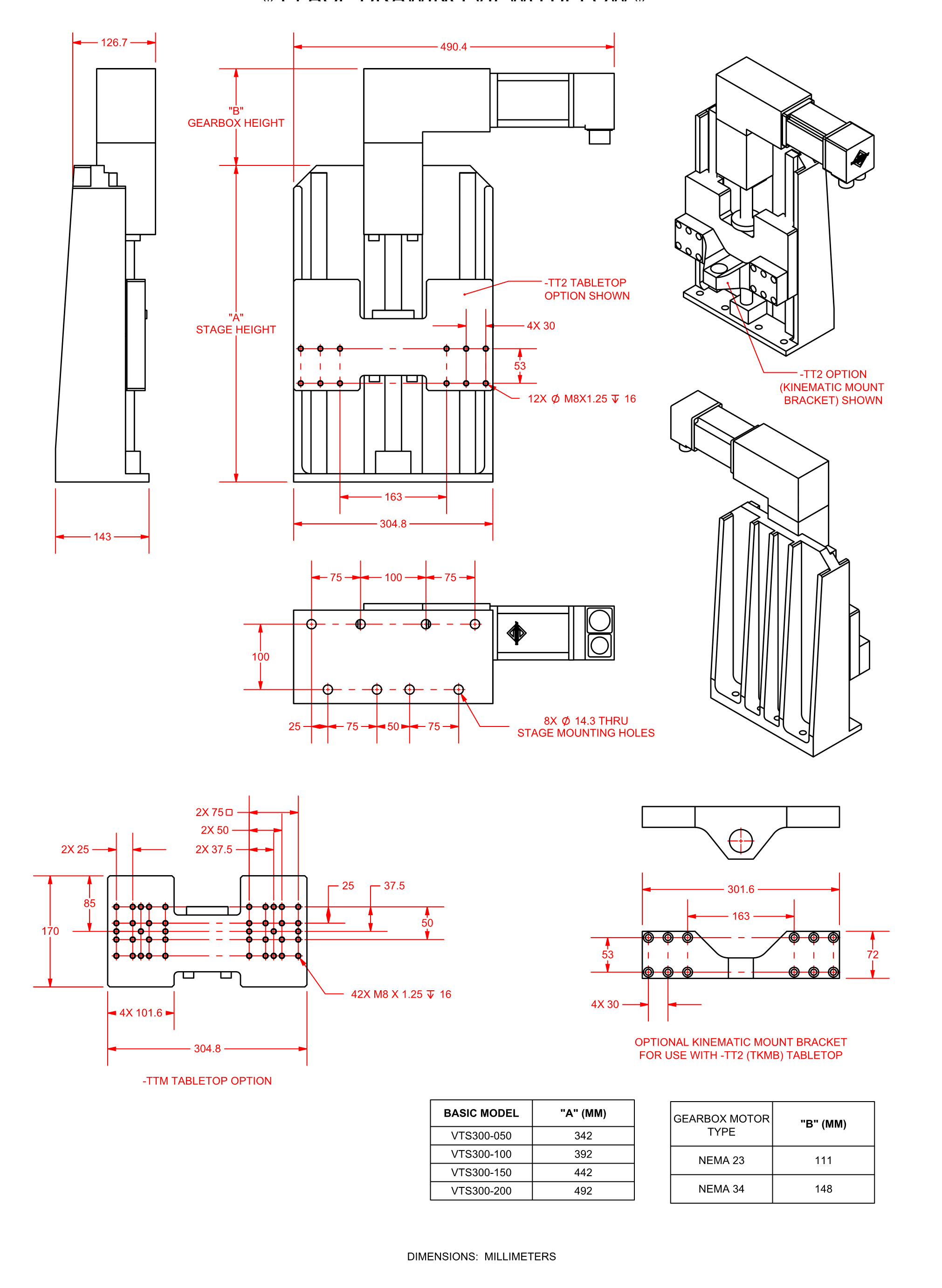

VTS300 Mechanical-Bearing Screw-Driven Lift Stage

Our VTS300 accurately positions loads up to 450 kg, and the small volume allows the positioning of high loads in space-constricted applications. Typical applications range from step and settle placement to large force generation. Multiple units can be combined for lift and tip/tilt motion.

Description

Specifications

Dimensions

Ordering Info

Downloads

Description

Description

Specifications

Dimensions

Ordering Info

Downloads

Description

Design Features

- Extreme load carrying capability, up to 450 kg, in a compact package

- Small stage footprint

- Lead screw does not back-drive, allowing "set and forget" operation and excellent in-position stability

- Vacuum compatible

Outstanding Design and Construction Features

The VTS300 series stages incorporate the highest quality components to provide superior positioning performance over a long lifetime. The base and table are fabricated from high hardness, high stiffness special alloy aluminum.

Pre-loaded angular contact ball-bearings support the 0.1 inch/rev precision lead-screw. The table moves on linear motion guide bearings providing excellent payload capability and long-life, even with heavy offset loads. The linear bearings also provide outstanding accuracy as well as exceptional flatness and straightness specifications over the length of travel.

Angular contact ball-bearings transmit shear forces and support excellent translation characteristics even with heavy loads. The anodized tabletop has a steel insert to support a tooling ball upon which the load would rest, providing a point lift for tip/tilt configurations.

The VTS300 series stages are available with matched stepping or brushless servomotors. The motor drives a high capacity 90° gearbox.

Options Include Vacuum Preparation for 10-6 torr

A number of options increase the flexibility of the VTS300 series stages for a wide range of applications. Vacuum preparation for operation in vacuum chambers to 10-6 torr is available. The stage also has movable limit switches so that customers can adjust the travel range.

Ordering Information

Travel (Required)

| Option | Description |

| -050 | 50 mm travel |

| -100 | 100 mm travel |

| -150 | 150 mm travel |

| -200 | 200 mm travel |

Tabletop (Required)

| Option | Description |

| -TT1 | Tabletop with metric dimension mounting |

| -TT2 | Tabletop with features for kinematic mounting bracket |

Motor (Optional)

| Option | Description |

| -M1 | BM130 servo motor with 1000-line TTL encoder |

| -M2 | BM130 servo motor with 1000-line TTL encoder and holding brake |

| -M3 | BM250 servo motor with 1000-line TTL encoder |

| -M4 | BM250 servo motor with 1000-line TTL encoder and holding brake |

| -M5 | SM280 high-voltage stepper motor |

Motor Orientation (Optional)

| Option | Description |

| -2 | Rear cable exit |

| -3 | Left-side cable exit (Standard) |

| -5 | Right-side cable exit |

Limits (Required)

| Option | Description |

| -LI1 | Normally-closed limit switches |

| -LI2 | Normally-open limit switches |

Metrology (Optional)

| Option | Description |

| -PL5 | Metrology, Horizontal/Vertical Straightness Correction (HALSF) |

Integration (Required)

Aerotech offers both standard and custom integration services to help you get your system fully operational as quickly as possible. The following standard integration options are available for this system. Please consult Aerotech if you are unsure what level of integration is required, or if you desire custom integration support with your system.

| Option | Description |

| -TAS | Integration - Test as system Testing, integration, and documentation of a group of components as a complete system that will be used together (ex: drive, controller, and stage). This includes parameter file generation, system tuning, and documentation of the system configuration. |

| -TAC | Integration - Test as components Testing and integration of individual items as discrete components that ship together. This is typically used for spare parts, replacement parts, or items that will not be used together. These components may or may not be part of a larger system. |