AVS100/AVSI100 Series Mechanical-Bearing Screw-Driven Lift Stage

Aerotech’s AVS100 and AVSI100 series stages offer a solution for applications that require very small incremental movements in elevation above a horizontal plane. Low profiles and precise motion capability make these stages ideal for use in semiconductor wafer inspection and testing, fiberoptics assembly and inspection, automated tool alignment, machine vision inspection systems and laser machining applications.

Description

Specifications

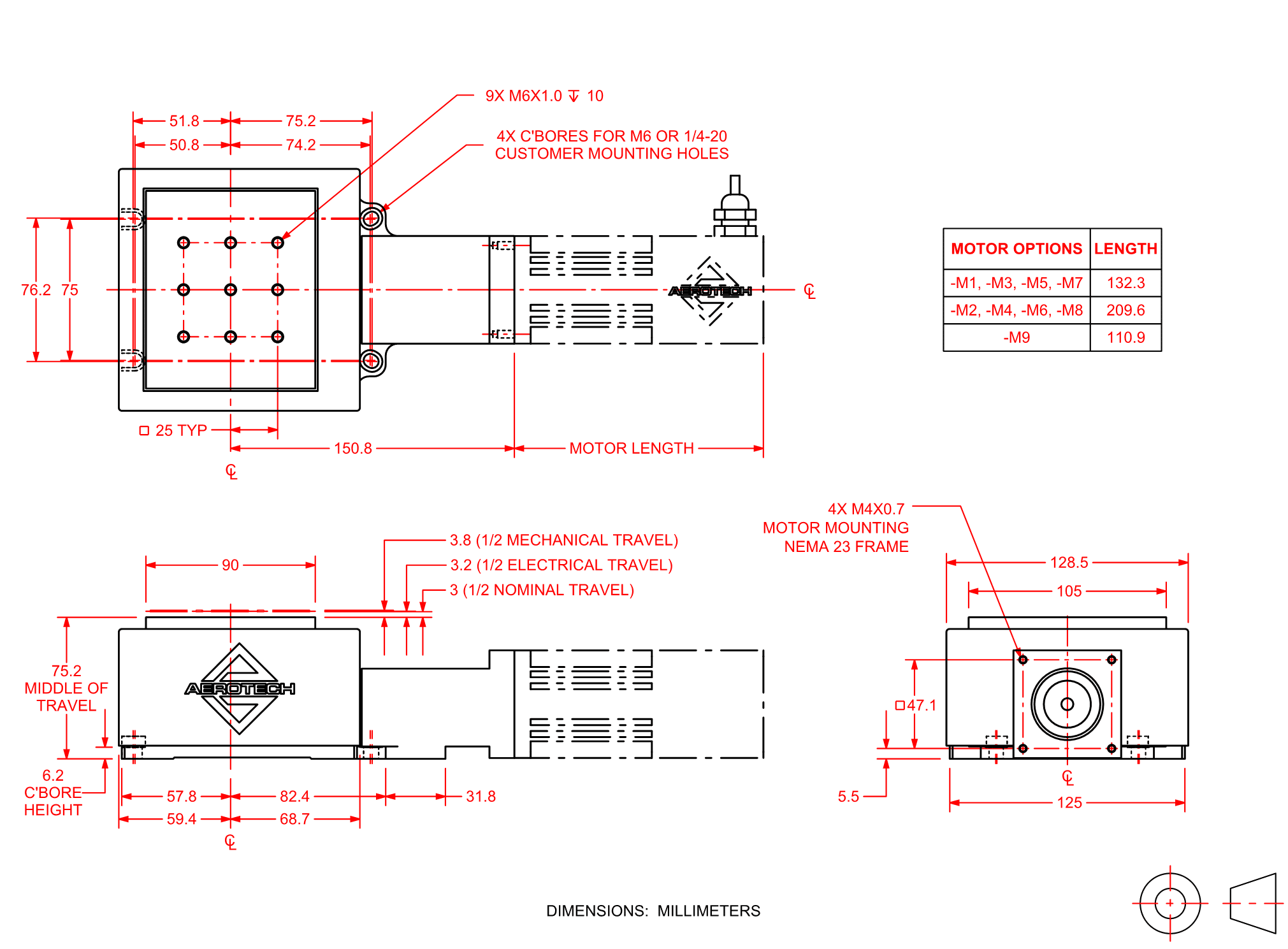

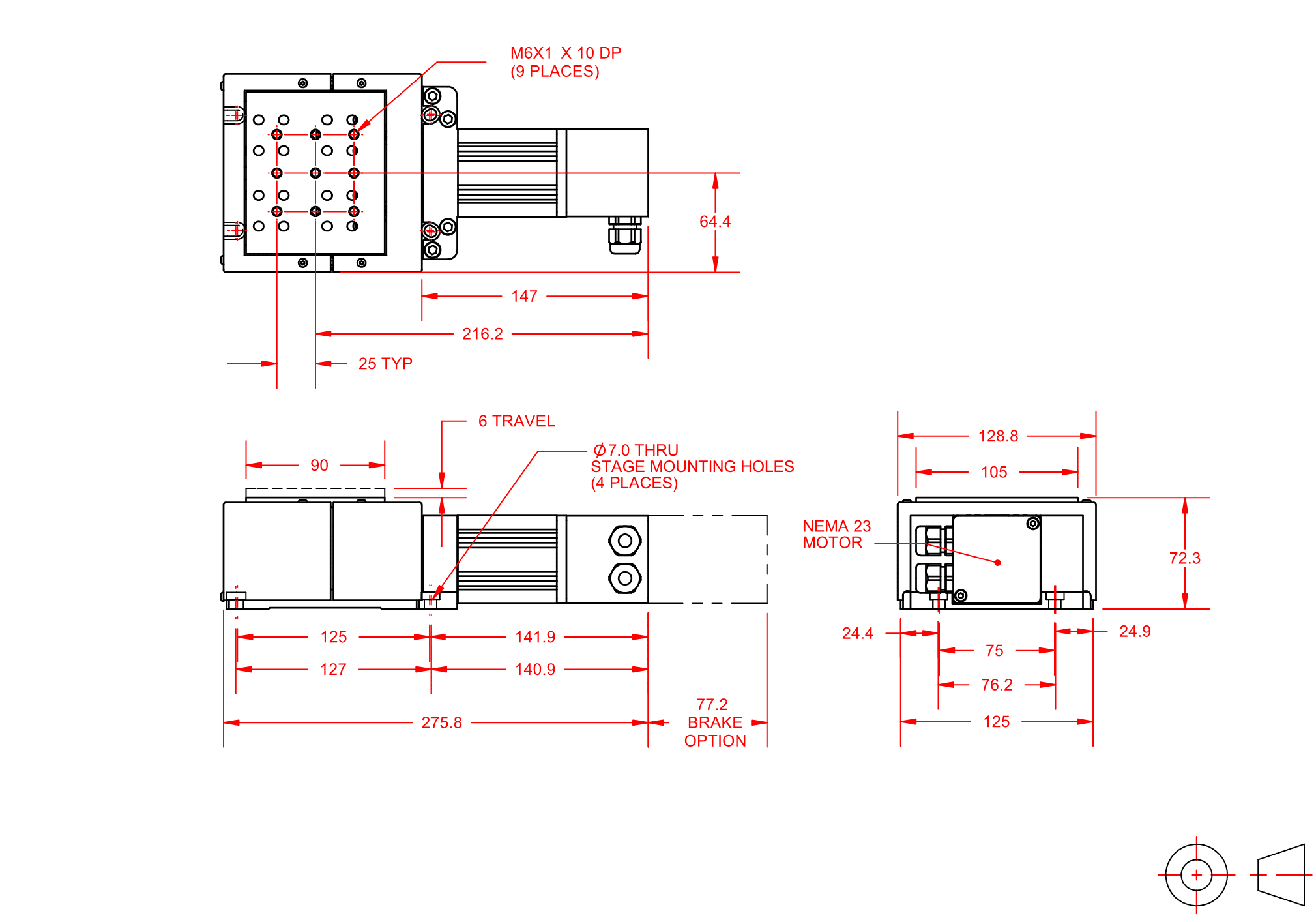

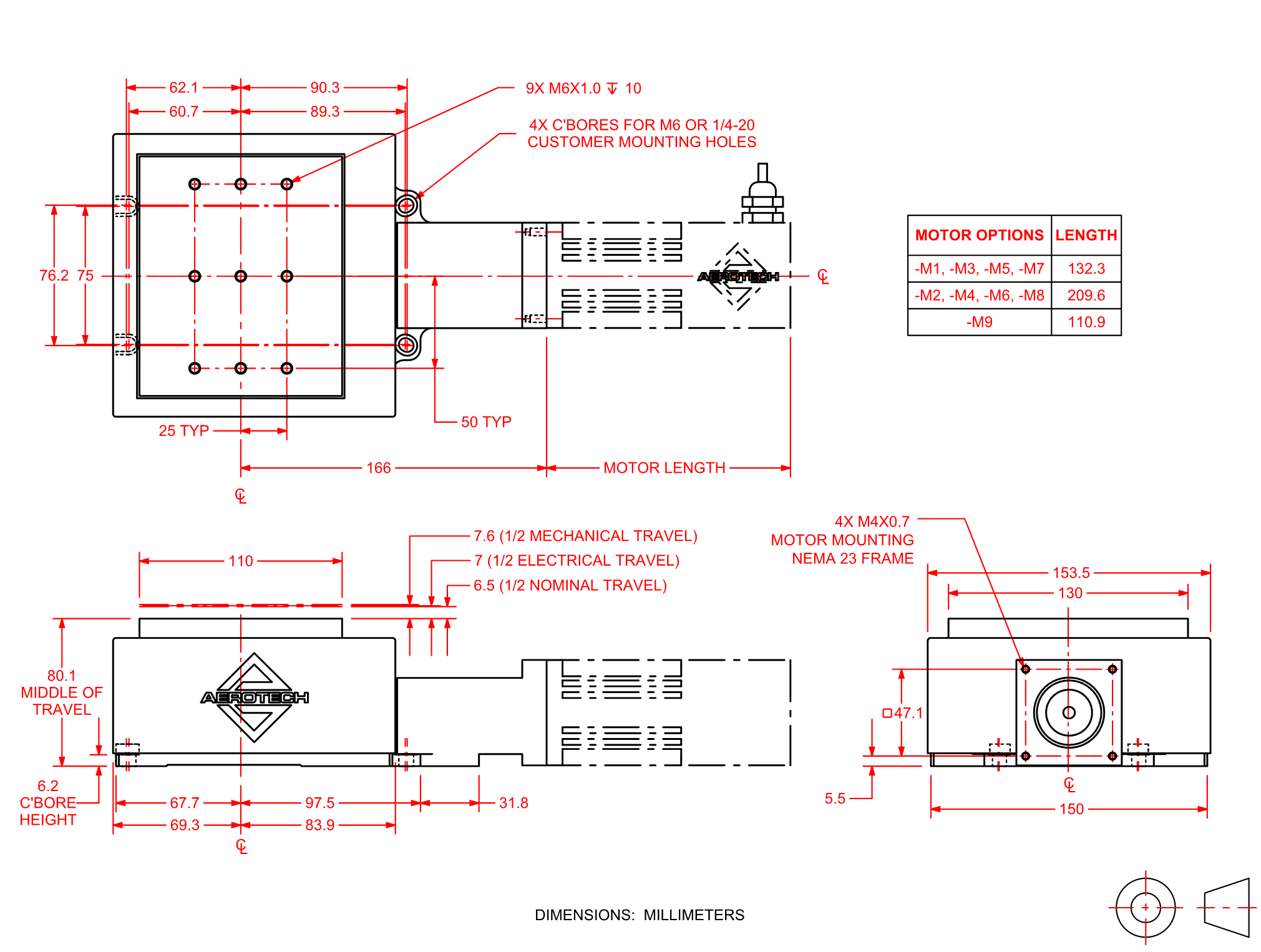

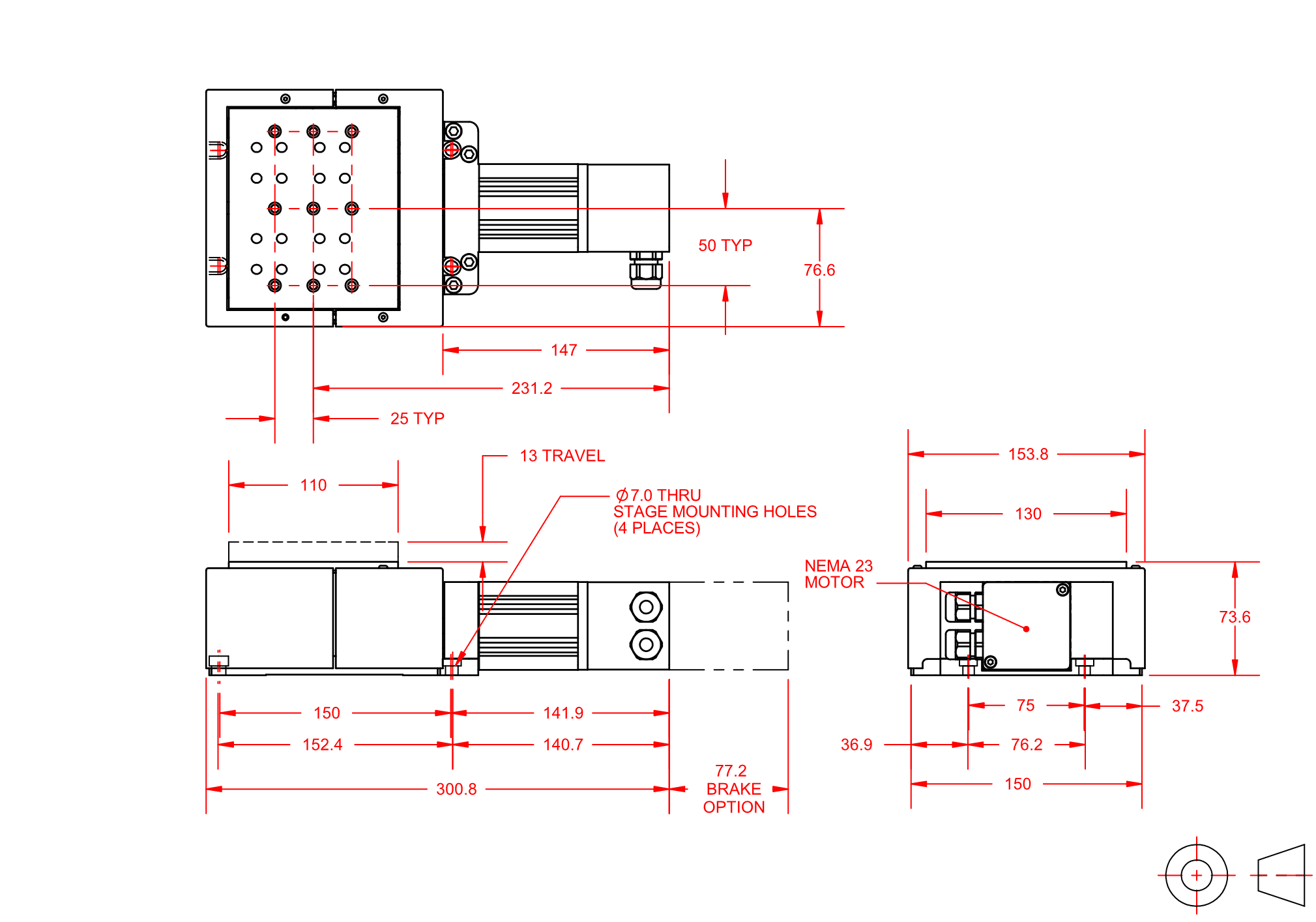

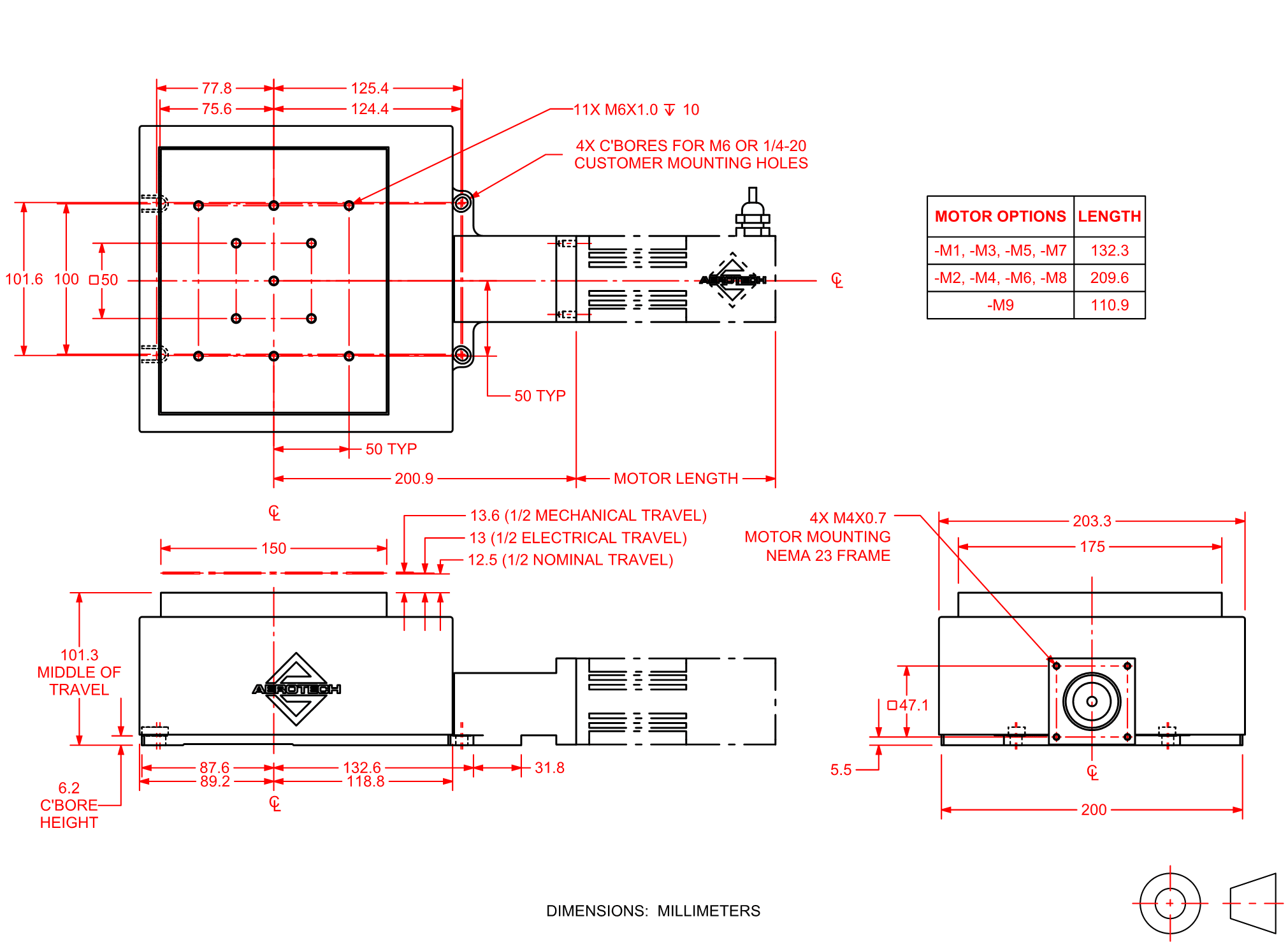

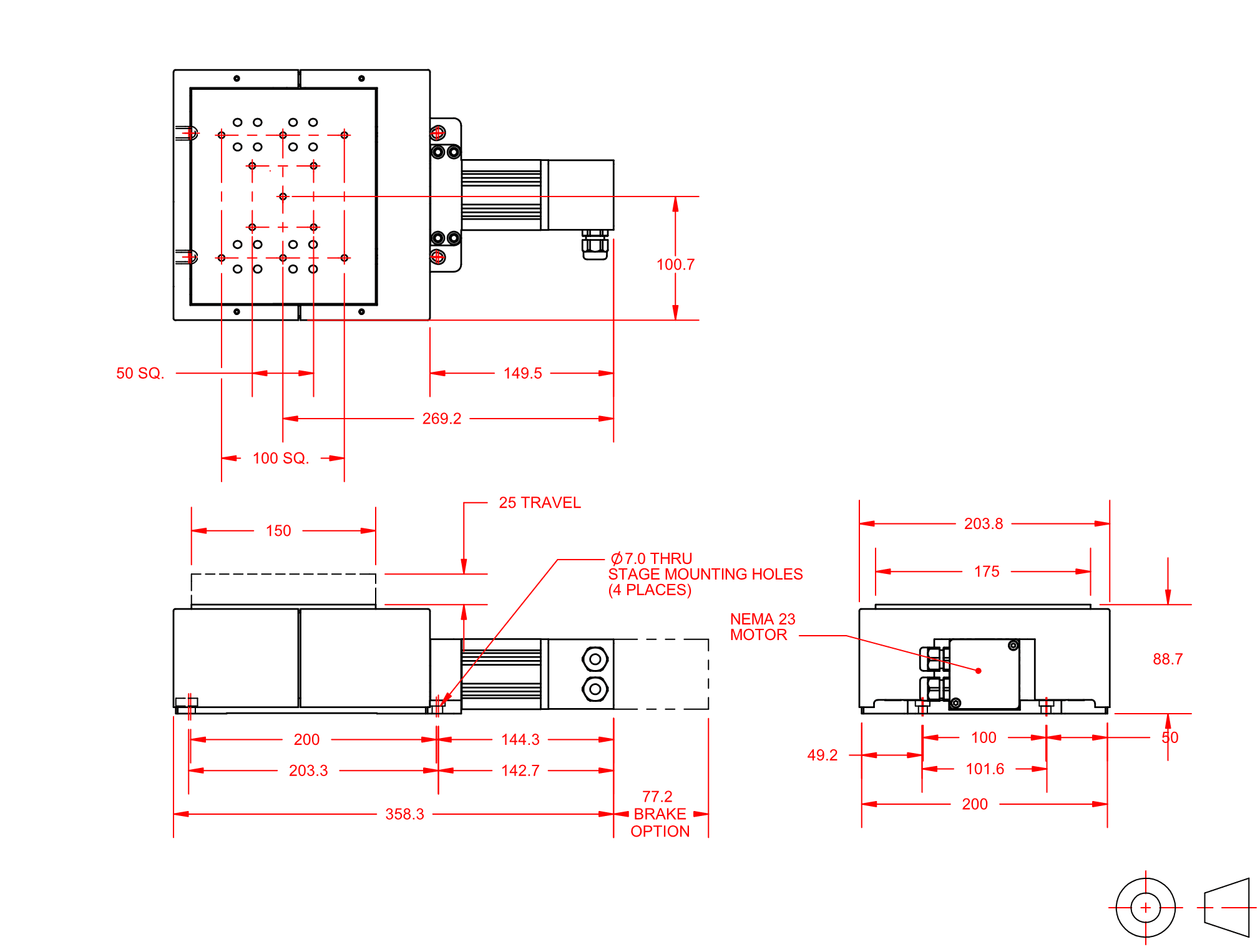

Dimensions

Ordering Info

Downloads

Description

Description

Specifications

Dimensions

Ordering Info

Downloads

Description

Design Features

- Long-life linear guide bearing system

- Submicron closed-loop positioning

- Low-cost, high-performance stage

- 6, 13 and 25 mm travel models

- Precision-ground ball screw

- Integral or removable motor

The AVSI100 series stages provide identical performance to the AVS100 stages, but in an even smaller footprint. The AVSI100 integrates the motor directly with the drive screw with no motor coupling. This makes the stage significantly shorter in length.

Quality Design Provides Superior Performance

The AVS100/AVSI100 series provides precise elevation of a load in a vertical plane. Rotational movement of a precision-ground ballscrew is converted into vertical elevation of the AVS100/AVSI100 series tabletop.

Sealed linear motion guide bearings with integral wipers are incorporated to provide excellent payload capability, long life, and smooth, precision motion. Stable and parallel vertical motion with no rocking or horizontal deviation of the platform is ensured.

Careful mechanical design allows the AVS100/AVSI100 series to achieve submicron resolution and still maintain a compact profile. The optional HALAR factory calibration option is available to further increase standard accuracy and repeatability.

A Better Approach to Vertical Motion

The vertical lift approach offers an alternative to traditional Z-plane oriented stages. Not only do the AVS100/AVSI100 series stages offer a lower profile, but the load can also be accessed easily from any side. And by centering the payload over the bearings, there are no cantilevering effects. The AVS100/AVSI100 series stages provide a space-saving alternative to traditional XYZ systems and are equally suited to laboratory and industrial applications. Optional stage finishes are available for various environments, including vacuum preparation.

Additional Standard Features

All AVS100/AVSI100 series stages are equipped standard with integral limit switches and mechanical hard stops. The stage tabletop is treated with a Teflon®-impregnated hardcoat (Rockwell 62 hardness) that is scratch-resistant and provides outstanding protection in the harshest environments. The stage itself has a black anodize finish.

Ordering Information

AVS100 Mechanical-Bearing Screw-Driven Lift Stage

Travel (Required)

| Option | Description |

| -06 | 6 mm Travel |

| -13 | 13 mm Travel |

| -25 | 25 mm Travel |

Motor (Optional)

| Option | Description |

| -M1 | BMS60 Servo Motor with 2500-Line TTL Encoder |

| -M2 | BMS60 Servo Motor with 2500-Line TTL Encoder and Holding Brake |

| -M3 | BMS60 Servo Motor with 1000-Line 1 Vpp Encoder |

| -M4 | BMS60 Servo Motor with 1000-Line 1 Vpp Encoder and Holding Brake |

| -M5 | BM75 Servo Motor with 2500-Line TTL Encoder |

| -M6 | BM75 Servo Motor with 2500-Line TTL Encoder and Holding Brake |

| -M7 | BM75 Servo Motor with 1000-Line 1 Vpp Encoder |

| -M8 | BM75 Servo Motor with 1000-Line 1 Vpp Encoder and Holding Brake |

| -M9 | SM60 High-Voltage Stepper Motor |

Foldback (Optional)

| Option | Description |

| -FB1 | Motor Foldback Kit for .250 Inch Diameter Shaft |

| -FB2 | Motor Foldback Kit with Brake for .250 Inch Diameter Shaft |

Motor Orientation (Optional)

| Option | Description |

| -2 | Bottom Cable Exit |

| -3 | Left-Side Cable Exit (Standard) |

| -4 | Top Cable Exit |

| -5 | Right-Side Cable Exit |

| -8 | Right-Side Foldback |

| -12 | Left-Side Foldback |

Limits (Required)

| Option | Description |

| -LI1 | Normally-Closed Limit Switches, 9-Pin D Connector |

| -LI2 | Normally-Closed Limit Switches, Flying Leads |

| -LI3 | Normally-Open Limit Switches, 9-Pin D Connector |

| -LI4 | Normally-Open Limit Switches, Flying Leads |

Coupling (Optional)

| Option | Description |

| -CP1 | Coupling for 0.250 Inch Diameter Shaft |

| -CP2 | Coupling for 0.375 Inch Diameter Shaft |

Metrology (Required)

| Option | Description |

| -PL1 | Metrology, Uncalibrated with Performance Plots |

| -PL2 | Metrology, Calibrated (HALAR) with Performance Plots |

Integration (Required)

Aerotech offers both standard and custom integration services to help you get your system fully operational as quickly as possible. The following standard integration options are available for this system. Please consult Aerotech if you are unsure what level of integration is required, or if you desire custom integration support with your system.

| Option | Description |

| -TAS | Integration - Test as system Testing, integration, and documentation of a group of components as a complete system that will be used together (ex: drive, controller, and stage). This includes parameter file generation, system tuning, and documentation of the system configuration. |

| -TAC | Integration - Test as components Testing and integration of individual items as discrete components. This is typically used for spare parts, replacement parts, or items that will not be used or shipped together (ex: stage only). These components may or may not be part of a larger system. |

AVSI100 Mechanical-Bearing Integrated Motor Screw-Driven Lift Stage

Travel (Required)

| Option | Description |

| -06 | 6 mm Travel |

| -13 | 13 mm Travel |

| -25 | 25 mm Travel |

Motor (Optional)

| Option | Description |

| -M1 | BMS60 Servo Motor with 2500-Line TTL Encoder |

| -M2 | BMS60 Servo Motor with 2500-Line TTL Encoder and Holding Brake |

| -M3 | BMS60 Servo Motor with 1000-Line 1 Vpp Encoder |

| -M4 | BMS60 Servo Motor with 1000-Line 1 Vpp Encoder and Holding Brake |

Motor Orientation (Optional)

| Option | Description |

| -3 | Left-Side Cable Exit (Standard) |

| -5 | Right-Side Cable Exit |

Limits (Required)

| Option | Description |

| -LI1 | Normally-Closed Limit Switches |

| -LI3 | Normally-Open Limit Switches |

Metrology (Required)

| Options | Descripton |

| -PL1 | Metrology, Uncalibrated with Performance Plots |

| -PL2 | Metrology, Calibrated (HALAR) with Performance Plots |

Integration (Required)

Aerotech offers both standard and custom integration services to help you get your system fully operational as quickly as possible. The following standard integration options are available for this system. Please consult Aerotech if you are unsure what level of integration is required, or if you desire custom integration support with your system.

| Options | Description |

| -TAS | Integration - Test as system Testing, integration, and documentation of a group of components as a complete system that will be used together (ex: drive, controller, and stage). This includes parameter file generation, system tuning, and documentation of the system configuration. |

| -TAC | Integration - Test as components Testing and integration of individual items as discrete components that ship together. This is typically used for spare parts, replacement parts, or items that will not be used together. These components may or may not be part of a larger system. |