BMS Series Brushless, Slotless Rotary Motors

Aerotech’s BMS series brushless, slotless servomotors represent the ultimate in high-performance rotary motors. Available in standard NEMA frame sizes, these motors utilize a slotless stator design for superior velocity smoothness and control. Featuring rare-earth magnets and a high pole-count rotor, the BMS series provides extremely smooth velocity control in a small package. Custom mechanical or electrical variations of the BMS can be engineered with minimal lead time.

Interested in buying online? Learn more here.

Description

Specifications

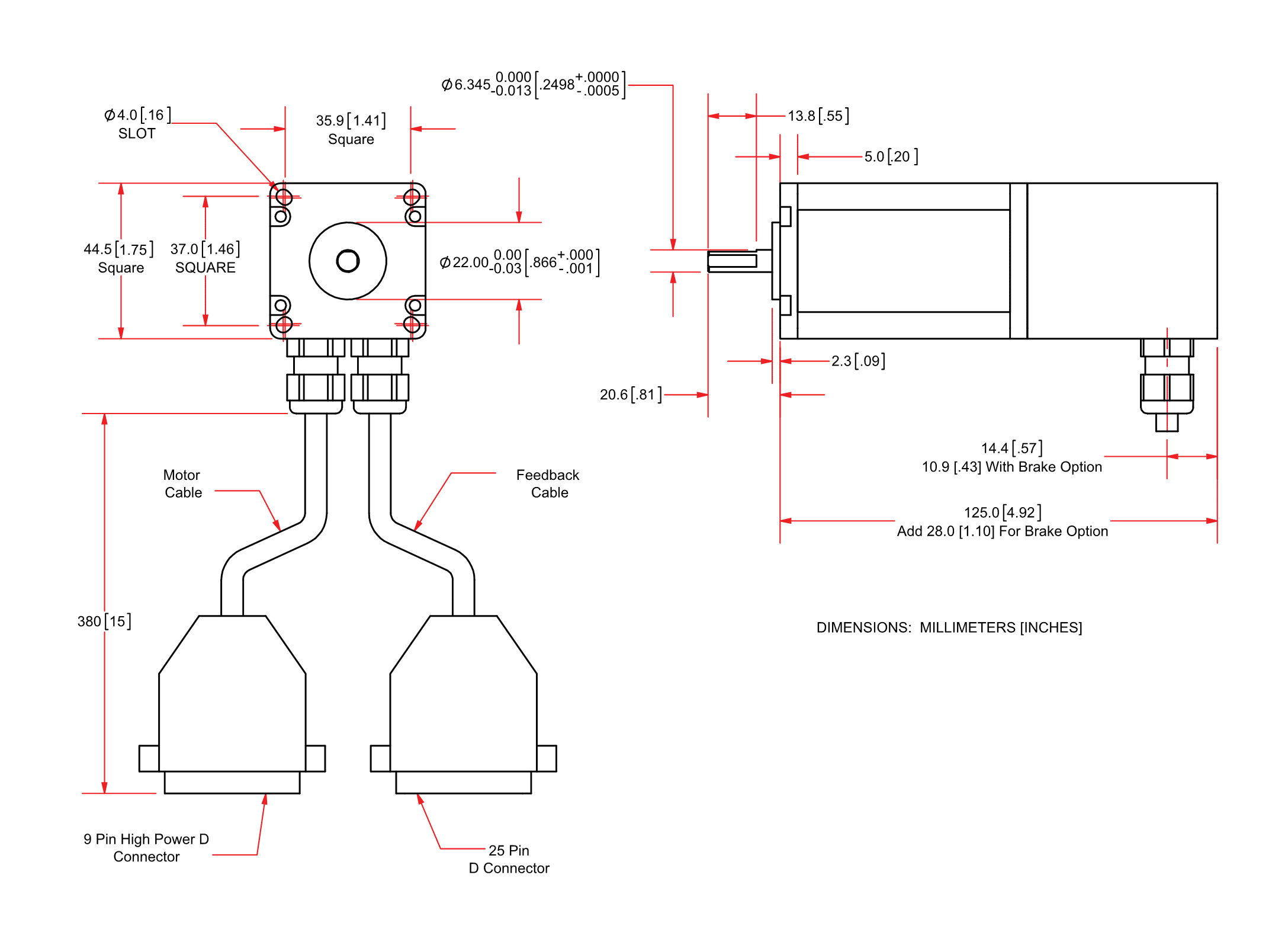

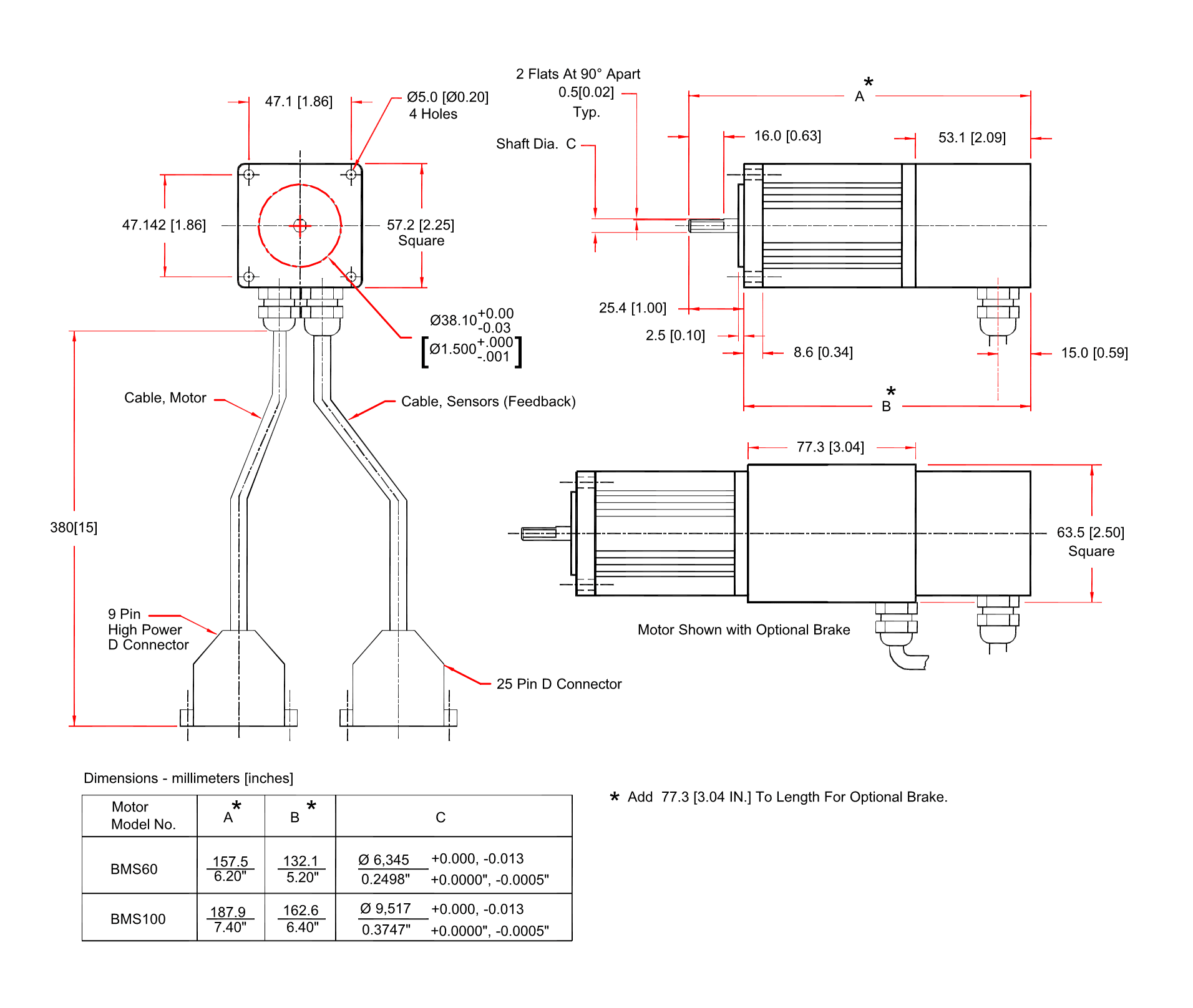

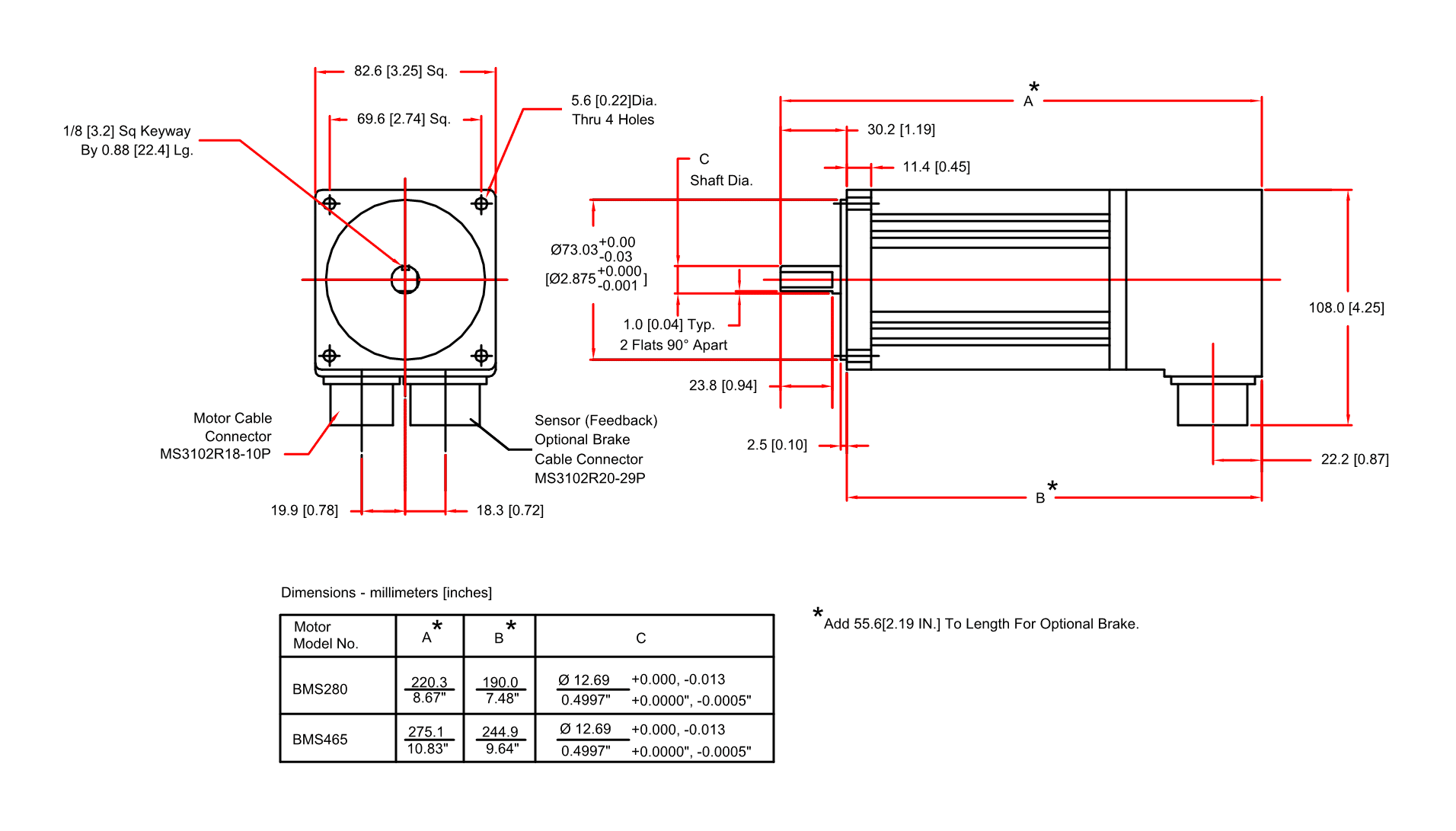

Dimensions

Ordering Info

Downloads

Description

Description

Specifications

Dimensions

Ordering Info

Downloads

Description

Design Features

- Slotless, brushless stator design provides zero cogging torque for unsurpassed velocity control

- Smoother velocity than with standard DC brush-type motors with the advantage of reliable brushless technology

- Standard NEMA frame sizes

- Ultra-high resolution capability with amplified sine-wave encoder and multiplier

- CE approved, follows the EU 2015/863 RoHS 3 directive

Smoother than DC Motors

The BMS series motors can replace standard brushless or brush-type motors when superior velocity smoothness and control are required. DC brush-type motors have been popular in applications such as machine tool and scanning because of their smooth low-speed control. The BMS motors provide superior smoothness and have higher acceleration capability than a DC brush motor. Higher acceleration results in higher machine throughput and performance.

High Performance Design

The BMS series is unlike conventional brushless servomotors because it incorporates a totally slotless stator design that provides the ultimate in smooth velocity control. These motors are designed for applications requiring superior torque and stability performance. The unique design of the BMS series motors provides a closer inertia match with mechanical systems than comparable models. This means better stability and easier tuning.

Ultra-High Encoder Resolution

The BMS series motors can be equipped with a variety of encoder resolution options for any application. In addition to the standard RS-422 line driver output, an optional amplified sine-wave encoder can be used to provide ultra-high resolution. Aerotech offers encoder multipliers as an option for drives connected to the A3200 system, as well as external multiplier boxes. Resolutions as high as 1,000,000 counts per revolution are achievable.

Need help sizing your motor? Try Aerotech's Motor Sizer software to specify the ideal motor for your application.

Ordering Information

NEMA Brushless slotless Rotary Servomotors

| Option | Description |

| BMS35 | NEMA17 Brushless slotless rotary servomotor |

| BMS60 | NEMA23 Brushless slotless rotary servomotor |

| BMS100 | NEMA23 Brushless slotless rotary servomotor |

| BMS280 | NEMA34 Brushless slotless rotary servomotor |

| BMS465 | NEMA34 Brushless slotless rotary servomotor |

Motor Winding (Required)

| Option | Description |

| -A | Motor winding |

- Contact factory to inquire about or check availability of alternate winding options.

Connectors (Required)

| Option | Description |

| -MS | Integral cable w/MS connector for Fbk and Mtr (-MS); not available for BMS35 |

| -D25 | Integral cable w/D25 Fbk and 4D Mtr (-D25); not available for BMS280 or BMS465 |

| -D25-9D | Integral cable w/D25 Fbk, 4D Mtr, and 9D Limit (-D25-9D); not available for BMS280 or BMS465 |

| -D25-FLB | Integral cable w/D25 Fbk, Fly Leads for Mtr, and 9D Limit (-D25-FLB); not available for BMS280 or BMS465 |

| -D25-5DU | Integral cable w/D25 Fbk, 5D Mtr, and 9D Limit (-D25-5DU); not available for BMS280 or BMS465 |

| -D25-9D-CMS | Integral cable w/D25 Fbk, 4D Mtr, and 9D Limit - CMS only (-D25-9D-CMS); not available for BMS280 or BMS465 |

| -D25-4TS | Integral cable w/D25 Fbk, 4TS Mtr, and 9D Limit (-D25-4TS); not available for BMS280 or BMS465 |

Feedback (Required)

| Option | Description |

| -E1000H | 1000 lines/rev TTL incremental encoder w/Hall tracks |

| -E2000H | 2000 lines/rev TTL incremental encoder w/Hall tracks |

| -E2500H | 2500 lines/rev TTL incremental encoder w/Hall tracks; not available for BMS35 |

| -E5000H | 5000 lines/rev TTL incremental encoder w/Hall tracks |

| -E1000ASH | 1000 lines/rev 1 Vpp incremental encoder w/Hall tracks |

Brake (Optional)

| Option | Description |

| -BK | Holding brake (-BK) |

Cable Type (Optional)

| Option | Description |

| -HF | High flex cable; not available for BMS280 or BMS465 |

Cable Length (dm) (Optional)

| Option | Description |

| -xx | Cable length in decimeters (3.8 dm is default) |

- Not available for BMS280 or BMS465.

Vacuum Preparation (Optional)

| Option | Description |

| -VAC6 | Vacuum preparation to 10-6 Torr |

Accessories (Optional)

| Option | Description |

| MC-HPD25-M | Connector; HPD motor power mate |

| MC-DB25-F | Connector; DB25 motor feedback mate |

| MCM-3 | Connector; MS motor power mate |

| MCF-3 | Connector; MS motor feedback mate |

- Accessories are ordered as separate line items.