BLMC Series Linear Motors

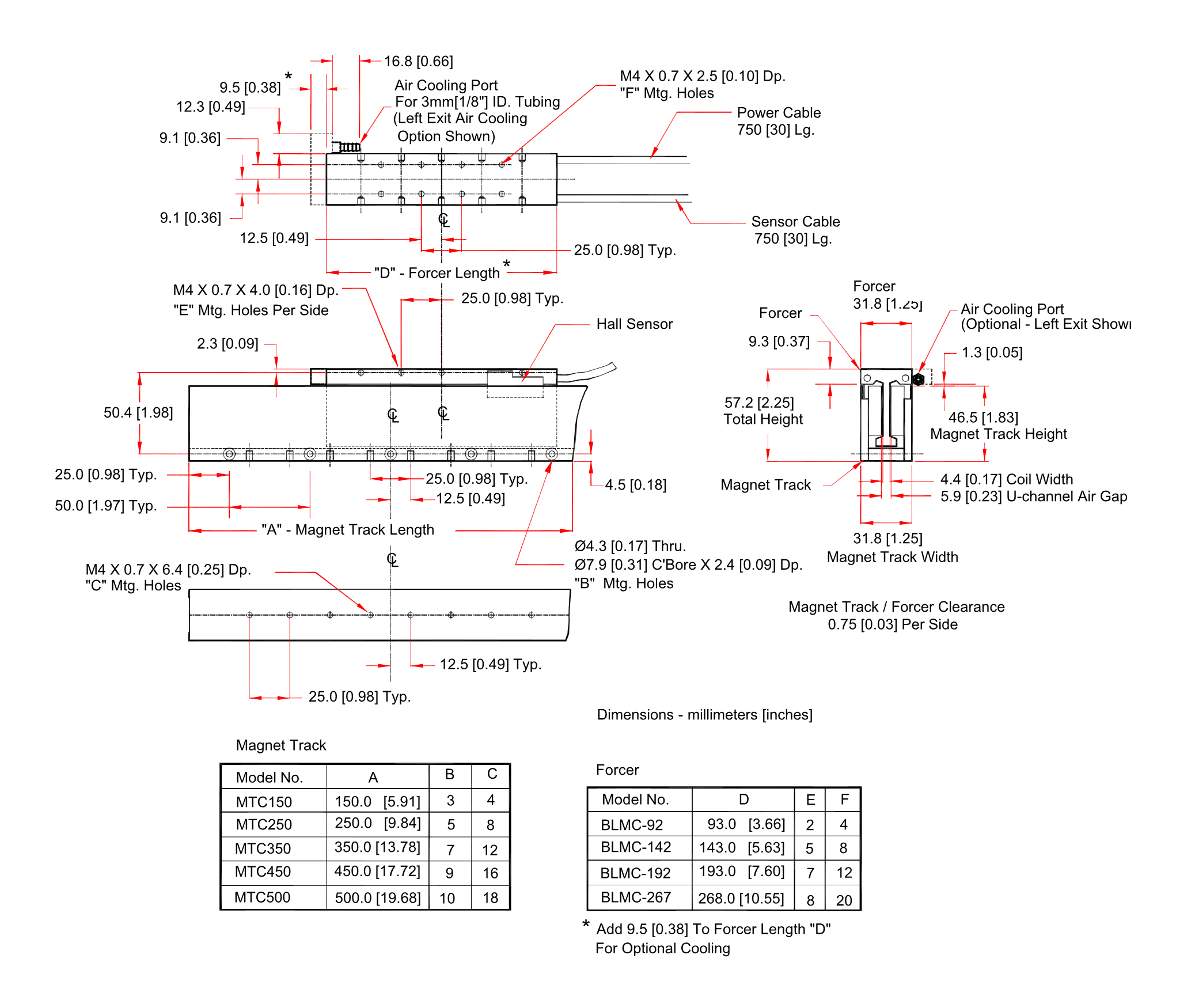

Aerotech’s “U-channel” BLMC series compact linear motors are only 57.2 mm x 31.8 mm and are designed for high force in a compact package.

Description

Specifications

Dimensions

Ordering Info

Downloads

Description

Description

Specifications

Dimensions

Ordering Info

Downloads

Description

Design Features

- Compact size for tight space constraints; 57.2 mm x 31.8 mm cross section

- Continuous force to 184.0 N (41.4 lb); peak force to 736.0 N (165.5 lb)

- Non-magnetic forcer coil provides high force with zero cogging for super-smooth velocity and position control

- Optional cooling for higher rms force

- CE approved, follows the EU 2015/863 RoHS 3 directive

Ideal for both high-accuracy positioning and high-throughput applications, BLMC series motors are direct drive and consist of a noncontacting forcer and "U-channel" rare-earth magnet track. This design eliminates backlash, windup, wear, and maintenance issues associated with ball screws, belts, and rack and pinions.

The compact forcer assembly contains Hall-effect devices, and a thermal sensor, and is constructed of reinforced ceramic epoxy. This ironless design eliminates eddy-current losses that otherwise would limit speed and produce additional heat. For highest rms force, optional air cooling is available. Offering high peak forces in its standard configuration, BLMC motors are available with special high-power magnets that can increase output force.

The BLMC series nonmagnetic forcer eliminates cogging and magnetic attraction to allow for extremely smooth motion and very tight velocity and position control. These linear motors are ideal for any application that requires high levels of positioning resolution and accuracy. BLMC series linear motors are forgiving to align, easy to assemble, and keep the magnetic field well-contained. Magnet tracks are stackable for any travel length. They are also suited for cleanroom use as they produce no particulates.

The BLMC can be driven using standard Aerotech brushless amplifiers and controllers to provide a complete integrated system.

Need help sizing your motor? Try Aerotech's Motor Sizer software to specify the ideal motor for your application.

Ordering Information

BLMC Brushless Linear Servomotor

| Option | Description |

| BLMC-92 | Linear motor forcer with thermistor; 92 mm long |

| BLMC-142 | Linear motor forcer with thermistor; 142 mm long |

| BLMC-192 | Linear motor forcer with thermistor; 192 mm long |

| BLMC-267 | Linear motor forcer with thermistor;267 mm long |

Winding Designation (Required)

| Option | Description |

| -A | 76 cm (2.5 ft) flying leads (standard) |

Air Cooling (Required)

| Option | Description |

| -NC | No air cooling fitting is installed |

| -ACC | Air cooling, rear center fitting installed; not available with the -V option |

| -ACL | Air cooling, rear left-side fitting installed; not available with the -V option |

| -ACR | Air cooling, rear right-side fitting installed; not available with the -V option |

Hall Effect Sensors (Required)

| Option | Description |

| -H | Hall effect sensors included |

| -NH | No hall effect sensors included |

Preparation (Required)

| Option | Description |

| -S | Standard preparation |

| -V | Vacuum preparation to 10-6 Torr |

| -UHV | Ultra-high vacuum preparation, contact factory |

Cable Length (Required)

| Option | Description |

| -750 | 750 mm length high-flex cables |

| -5000 | 5.0 m length high-flex cables |

Magnet Tracks (Optional)

| Option | Descsription |

| MTC100P | "U" channel magnet track for use with BLMC-series forcers; 100 mm long |

| MTC150P | "U" channel magnet track for use with BLMC-series forcers; 150 mm long |

| MTC175P | "U" channel magnet track for use with BLMC-series forcers; 175 mm long |

| MTC200P | "U" channel magnet track for use with BLMC-series forcers; 200 mm long |

| MTC250P | "U" channel magnet track for use with BLMC-series forcers; 250 mm long |

| MTC300P | "U" channel magnet track for use with BLMC-series forcers; 300 mm long |

| MTC350P | "U" channel magnet track for use with BLMC-series forcers; 350 mm long |

| MTC425P | "U" channel magnet track for use with BLMC-series forcers; 425 mm long |

| MTC450P | "U" channel magnet track for use with BLMC-series forcers; 450 mm long |

| MTC500P | "U" channel magnet track for use with BLMC-series forcers; 500 mm long |

| MTCxP | "U" channel magnet track for use with BLMC-series forcers; custom length |

| MTC150S | "U" channel magnet track for use with BLMC-series forcers; 150 mm long |

| MTC200S | "U" channel magnet track for use with BLMC-series forcers; 200 mm long |

| MTC250S | "U" channel magnet track for use with BLMC-series forcers; 250 mm long |

| MTC300S | "U" channel magnet track for use with BLMC-series forcers; 300 mm long |

| MTC350S | "U" channel magnet track for use with BLMC-series forcers; 350 mm long |

| MTC425S | "U" channel magnet track for use with BLMC-series forcers; 425 mm long |

| MTC450S | "U" channel magnet track for use with BLMC-series forcers; 450 mm long |

| MTC500S | "U" channel magnet track for use with BLMC-series forcers; 500 mm long |

| MTCxS | "U" channel magnet track for use with BLMC-series forcers; custom length |

- Magnet tracks are ordered as separate line items. Magnet track part numbers ending with “P” are high performance grade, including magnets on both sides of the track. Magnet track numbers ending with “S” are standard performance grade, including magnets on a single side of the track.

Integration (Required)

Aerotech offers both standard and custom integration services to help you get your system fully operational as quickly as possible. The following standard integration options are available for this system. Please consult Aerotech if you are unsure what level of integration is required, or if you desire custom integration support with your system.

| Option | Description |

| -TAS | Integration - Test as system Testing, integration, and documentation of a group of components as a complete system that will be used together (ex: drive, controller, and stage). This includes parameter file generation, system tuning, and documentation of the system configuration. |

| -TAC | Integration - Test as components Testing and integration of individual items as discrete components that ship together. This is typically used for spare parts, replacement parts, or items that will not be used together. These components may or may not be part of a larger system. |