Automation1 XC2 Compact PWM Servo Drive

The Automation1 XC2 pulse-width modulation (PWM) servo motor drive is our smallest panel-mount drive. Packed with standard features–including safe torque off (STO) and a drive array with more than 16.7 MB of memory–it also has expansion options like analog and digital input/output (I/O), multi-axis position synchronized outputs (PSO), a feedback multiplier and more.

You’ll achieve excellent motion control performance with the XC2. The servo and current loops are closed at 20 kHz, and digital and analog outputs are set and inputs are collected at 20 kHz.

Description

Specifications

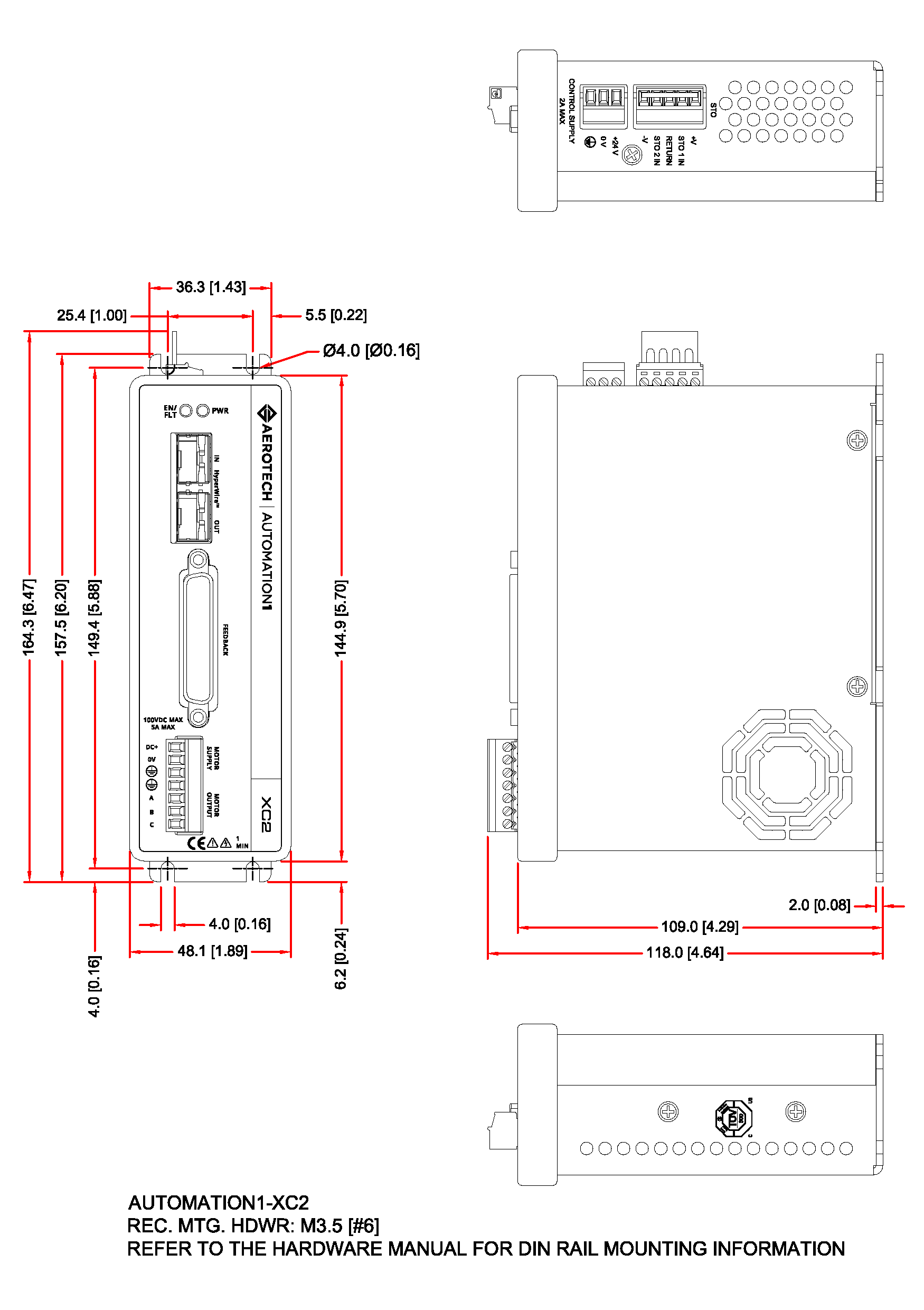

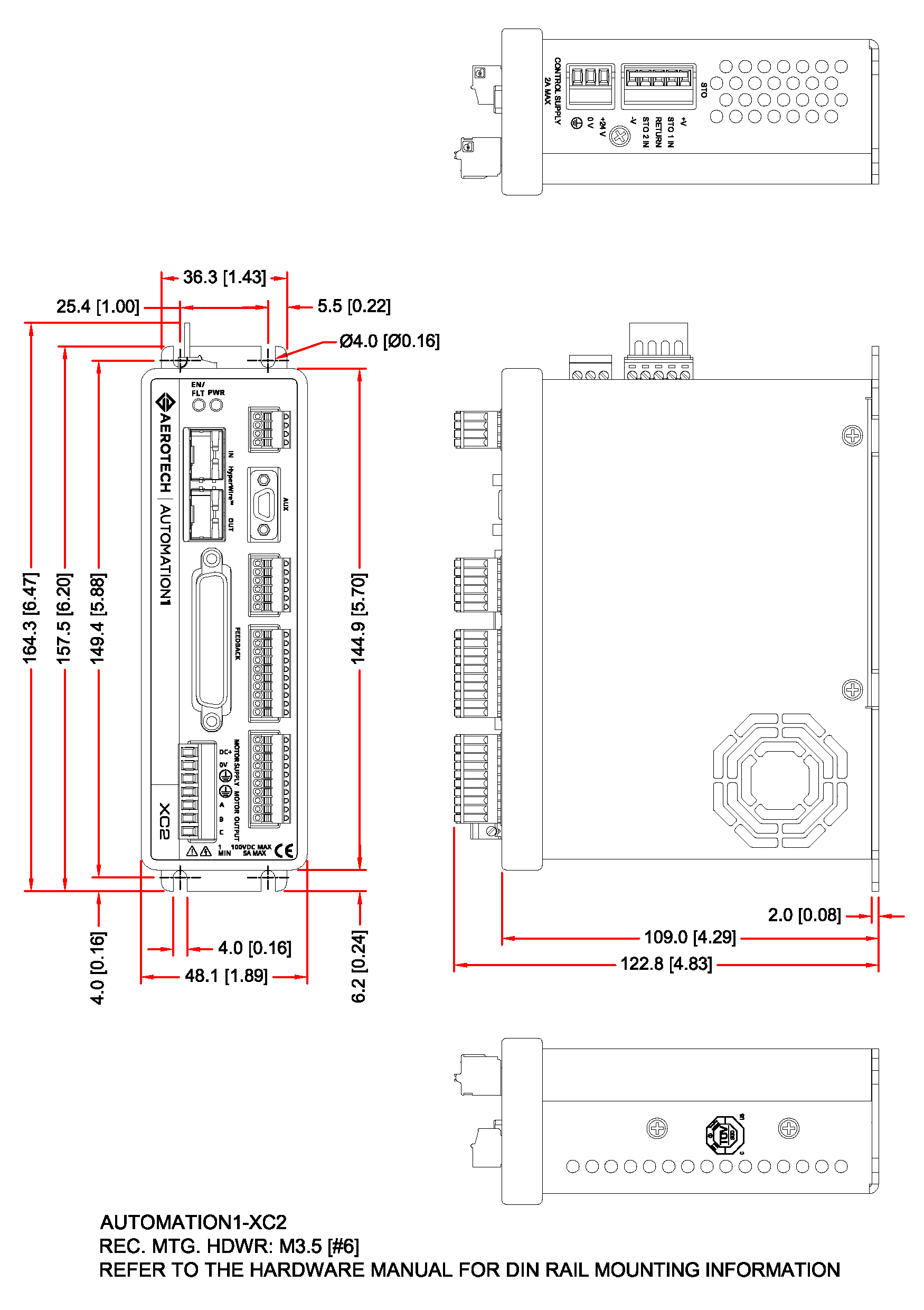

Dimensions

Ordering Info

Downloads

Description

Description

Specifications

Dimensions

Ordering Info

Downloads

Description

Design Features

- Connects through the HyperWire® fiberoptic bus, which has 20 times the bandwidth of 100BASE-T Ethernet buses

- Includes Safe Torque Off (STO) safety circuit

- Generates 100 VDC bus motor power & up to 10 amps peak output

- Features drive array with more than 16.7 MB of memory

- Collects analog sensor or position data up to 320 kHz (triggered by axis position)

- Offers many optional features, including Multi-axis Position Synchronized Output (PSO) and I/O expansion board

Automation1

The XC2 is a part of the user-friendly Automation1 motion control platform, which includes the following:

Better Control. More Precision

The XC2 connects to the Automation1 Intelligent Software-Based Machine Controller (iSMC) controller over fiber-optic HyperWire®, the fastest, highest-throughput communication bus in motion control.

You can use the XC2 PWM amplifiers to control brushless AC, brush DC, voice coil and stepper motor types at up to 100 VDC operating voltage and 10 A peak current capability.

Standard features for the XC2 include STO, a data array consisting of more than 4 million 32-bit elements (>16.7 MB), dedicated home and end-of-travel limit inputs, and an enhanced current sense device. Standard encoder support includes square-wave and absolute encoders.

Add I/O to your XC2 with an expansion board containing analog and digital I/O, an added encoder input, and dedicated PSO. Improve the resolution of amplified sine-wave encoders by adding a feedback multiplier.

Effortless Feedback

Aerotech’s standard feedback connector is a 25-pin DB-25 connector, which enables simple, single-cable connectivity for all feedback signals from a servo motor and precision stage combination. The XC2 is offered with or without an integral encoder multiplier, which enables design flexibility based on the resolution required by your application. Absolute encoder support is a standard feature.

Ready to Connect

Two HyperWire connections make it simple to connect the XC2 in a multi-axis configuration with other Automation1 drive hardware. A 24-volt one amp brake output is included. The device is CE approved, NRTL safety certified and EU 2015/863 RoHS 3 directive certified. The power amplifier bandwidth is software selectable and up to 95 percent efficient.

Capture Process Data

The XC2 collects multiple signals and data items that provide valuable diagnostic and performance information. When coupled with the two Gbps HyperWire bandwidth, you can pull the required data back to the iSMC for easy access via the Automation1 Studio application or the .NET application programming interface (API). Unlike other platforms, you never have to lower your trajectory rates to acquire this valuable data.

Excellent In-Position Performance

Thanks to advanced control techniques and feedback signal processing, the XC2 can control stage in-performance to as low as 0.2 nanometers rms.

See how Automation1 Servo Drives Improve In-Position Stability.

System Integration Made Simple

The small form-factor enables compact machine designs, while a four-axis system can be configured with more than 70 I/O points. The XC2 integrates easily with the Automation1 Software-Based Machine Controller (iSMC).

Feature |

10 |

| Motor Style | Brush, Brushless, voice coil, stepper_1 |

| Control Supply | 24 VDC |

| Motor Supply | 15-100 VDC |

| Bus Voltage_2 | 15-100 VDC |

| PWM Frequency | 20 kHz |

| Peak Output Current (1 sec)_3 | 10 Apk |

| Continuous Output Current_3 | 5 A |

| Position Synchronized Output (PSO) | Standard: One-axis PSO (includes One-axis Part-Speed PSO)* Optional: Three-axis Part-Speed PSO* *Requires adding an expansion board to the drive to output PSO pulses via a physical connection |

| 25-Pin Motor Feedback Connector | High-speed Differential Inputs (encoder sin, cos and marker) CW and CCW Limits Hall Effect Sensor Inputs (A, B, and C) Analog Motor Temperature Input (accepts digital) Brake output |

| Multiplier Options | MX0 Option: Primary Encoder: 40 million counts per second square-wave input. Auxiliary Encoder: 40 million counts per second square-wave input. MX1 Option: Primary Encoder: 200 kHz sine-wave input, encoder multiplier up to x16,384* Auxiliary Encoder: 40 million counts per second square-wave input *Encoders multiplied with this input cannot be echoed out. |

| I/O Expansion Board (-EB1) | PSO output connector with up to 12.5 MHz output rate Auxiliary Encoder Port 1x 16-bit differential, ±10 V analog input 1x 16-bit single-ended, ±10 V analog output 8x optically isolated digital inputs 8x optically isolated digital outputs |

| Drive Array Memory | 16.7 MB (4,194,304 32-bit elements) |

| High-Speed Data Capture | Yes (50 ns latency) |

| Safe Torque Off (STO) | Yes (SIL3/PLe/Cat 4) |

| HyperWire Connections | 2x HyperWire small form-factor pluggable (SFP) Ports |

| Automatic Brake Control | Standard; 24 V at 1 A |

| Absolute Encoder | Renishaw Resolute BiSS; EnDat 2.1; and EnDat 2.2 |

| Current Loop Update Rate | 20 kHz |

| Servo Loop Update Rate | 20 kHz |

| Power Amplifier Bandwidth | 2500 Hz maximum (software selectable) |

| Power Amplifier Efficiency | 85-95%_4 |

| Minimum Load Inductance | 0.1 mH |

| Operating Temperature | 0 to 40°C |

| Storage Temperature | -30 to 85 °C |

| Weight | 0.54 kg (1.20 lb.) |

| Compliance | CE approved, NRTL safety certification, EU 2015/863 RoHS 3 directive |

Ordering Information

Automation1 XC2

| Option | Description |

| Automation1 XC2 | Automation1 XC2 - Compact PWM Servo Drive |

Peak Current

| Option | Description |

| -10 | 10 A, 5 A cont. current (default) |

Expansion Board

| Option | Description |

| -EB0 | No expansion board (default) |

| -EB1 | IO expansion board |

Multiplier

| Option | Description |

| -MX0 | No encoder multiplier (default) |

| -MX1 | x16384 multiplier (primary), no multiplier (auxiliary) |

PSO

| Option(1)(2) | Description |

| -PS01 | One-Axis PSO (includes One-axis Part-Speed PSO) (Default) |

| -PSO6 | Three-axis Part-Speed PSO |

- PSO functionality is included in the base XC2. The -EB1 board is required to use PSO logic to generate an output signal.

- Encoder feedback-based PSO requires the -MX0 multiplier option.

Automation1 PS2

| Option | Description |

| Automation1 PS2 | Automation1 PS2 - Din-Rail Mounted Power Supply for 1 to 4 Compact Servo Drives |

Drive Type (Required)

| Option | Description |

| -D1 | PS2 for XC2 & XC2e Drives and iXC2e & iXC2 Drive-based Controllers |

| -D2 | PS2 for XL2e Drives and iXL2e Drive-based Controllers |

Power Output (Required)

| Option | Description |

| -P1 | 240 Watts at 24 VDC |

| -P2 | 240 Watts at 48 VDC |

| -P3 | 480 Watts at 48 VDC |

| -P4 | 480 Watts at 96 VDC |

| -P5 | 240 Watts at +/-12 VDC (10A) |

| -P6 | 240 Watts at +/-24 VDC (5A |

| -P7 | 480 Watts at +/-48 VDC (5A) |

Number of Axes (Required)

| Option | Description |

| -AX01 | 1 Axis of Wiring |

| -AX02 | 2 Axis of Wiring |

| -AX03 | 3 Axis of Wiring |

| -AX04 | 4 Axis of Wiring |